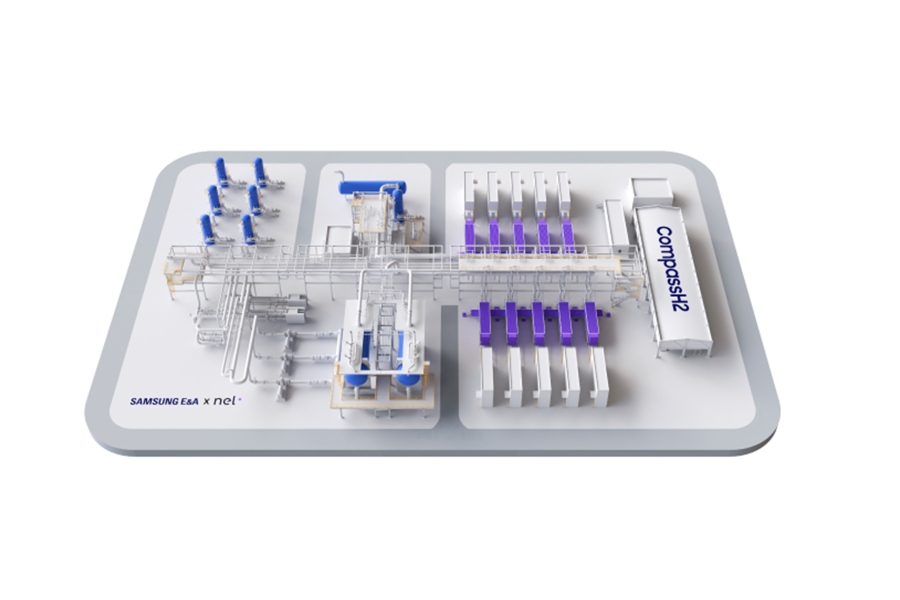

ITM Power to supply 710 MW of electrolyzers for German grid balancing

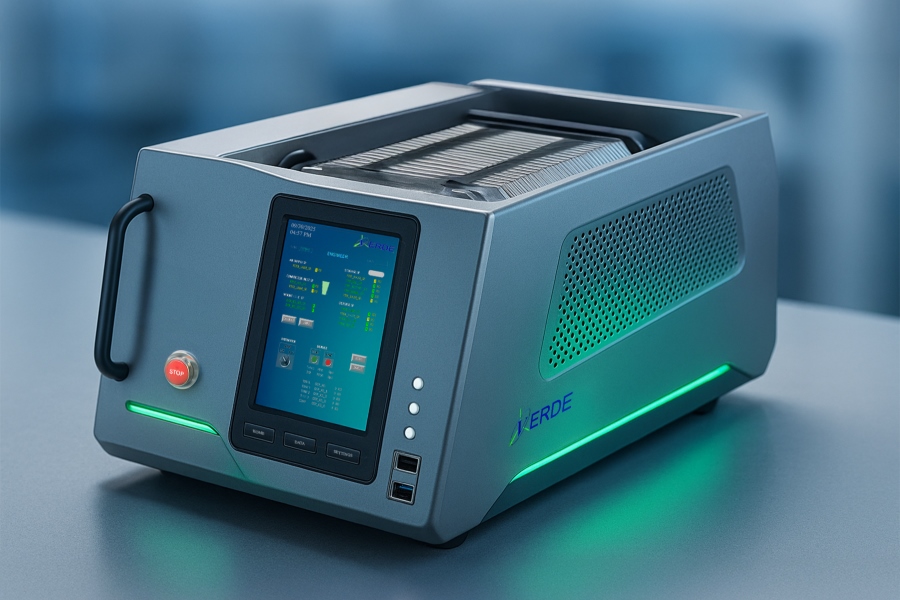

Stablegrid Group has selected ITM Power to supply 710 MW of proton exchange membrane (PEM) electrolyzer capacity for two German grid-balancing hydrogen projects designed to support system stability.