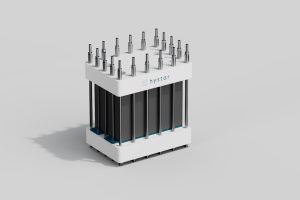

Built in cooperation with Siemens Energy, the water electrolyzer is embedded in the production and infrastructure at the Ludwigshafen site, making it truly unique in terms of its interface and integration into a chemical production environment. A total of 72 stacks have been installed in the system. The electrolyzer has the potential to reduce greenhouse gas emissions at BASF’s main plant by up to 72,000 metric tons per year.

The emission-free production of hydrogen – using electricity from renewable sources – is fundamental to the market ramp-up of chemical products with a reduced carbon footprint. Once produced, the hydrogen is fed into the site’s hydrogen Verbund network and distributed to the production facilities as a raw material. In addition to using it as a feedstock for chemical products, BASF plans to supply hydrogen for mobility in the Rhine-Neckar Metropolitan Region, supporting the development of a hydrogen economy in the area.

In cooperation with the State of Rhineland-Palatinate, the German Federal Ministry for Economic Affairs and Climate Action provided funding of up to €124.3 million for the construction of the plant – €37.3 million of which was financed by the government of Rhineland-Palatinate. BASF’s investment in the project amounts to around €25 million. The project, entitled Hy4Chem, was selected as part of the IPCEI Hydrogen expression of interest procedure and subsequently funded as an individual project.

Katja Scharpwinkel, member of BASF SE’s Board of Executive Directors and Site Director Ludwigshafen, said: “The commissioning of the electrolyzer makes it possible for us to support our customers in achieving their climate targets by offering them products with a lower carbon footprint. At the same time, we are gaining experience at our largest Verbund site with the integration and operation of a system that brings us another step closer to transforming our main plant in Ludwigshafen. We welcome the fact that the federal government and state government have recognized the importance of this technology and provided us with significant support toward the project’s implementation.”

Alexander Schweitzer, Minister-President of Rhineland-Palatinate, commented: “The commissioning of the electrolyzer at BASF for the production of green hydrogen is a milestone for the ramp-up of the hydrogen economy in Rhineland-Palatinate, Germany, and Europe and an important commitment of BASF to its technology and production site in Ludwigshafen. With the Hy4Chem project, BASF is impressively demonstrating how the transformation of the energy-intensive chemical industry can succeed – innovatively, sustainably, and internationally competitively. As the state government, we support this process with up to €37.3 million because we are convinced that hydrogen plays a key role in decarbonizing and securing our industrial jobs. Today’s inauguration sends a strong signal for a climate-neutral future and strengthens Ludwigshafen as a business location.”

Among other applications, hydrogen is used in the production of ammonia, methanol, and vitamins. Until now, hydrogen at Ludwigshafen has primarily been produced by means of natural gas-based steam reforming or as a coupling product or by-product. With the electrolyzer, BASF is now taking an important step towards the transformation of hydrogen production technology.