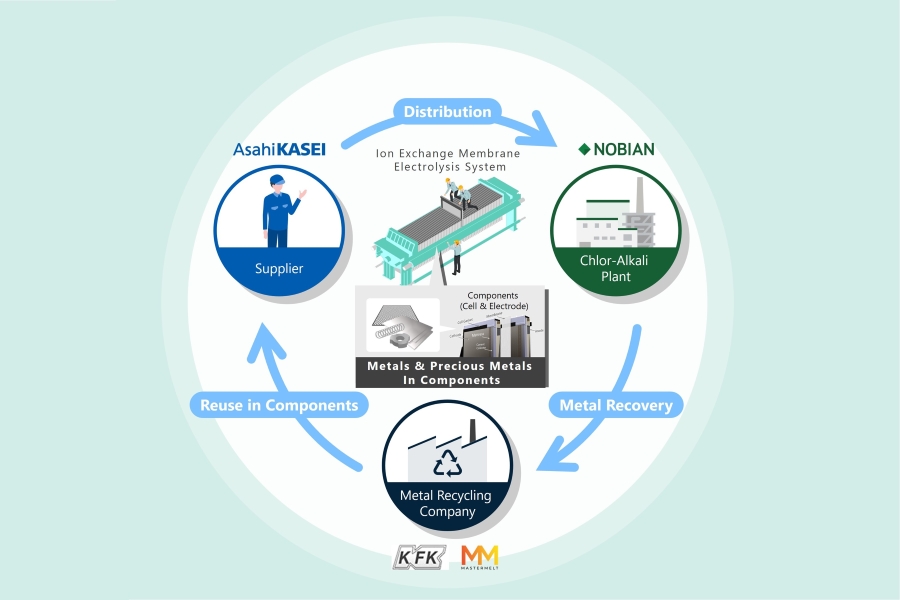

Through this initiative, which began in February 2025, the partners aim to build a recycling ecosystem for valuable metals within the chlor-alkali industry.

Precious metals such as iridium and ruthenium are essential for the production of electrodes and other components for electrolysis systems. With growing global demand for these materials, Asahi Kasei, whose broad portfolio includes ion-exchange membranes, electrolysis cells, electrodes, and operational expertise for electrolyzer plants, has been working with partners to ensure a stable and secure supply. One such example is a demonstration project launched in 2023 with Nobian, focusing on the reuse of precious metals through an electrolysis cell rental service in Europe.

The new recycling project with Nobian, Furuya Metal, and Mastermelt aims to establish a process for refining and reusing metals from end-of-life cells and electrodes as raw materials for the production of new components within the chlor-alkali industry. It is anticipated that this approach could also be extended to Asahi Kasei’s electrolysis systems for green hydrogen production.

Under the project, Asahi Kasei will collect end-of-life electrodes from Nobian and supply them to Mastermelt and Furuya Metal, which will remove the catalyst, prepare the material, and extract and purify the precious metals. Asahi Kasei will then use the recovered metals to create new catalysts, which will be applied to coat electrodes. These recycled catalytic electrodes will be used by Nobian for brine electrolysis, enabling resource recycling in caustic soda and chlorine production.

“This demonstration represents an important step forward for the chlor-alkali industry and furthers our commitment to advancing circular economy solutions,” said Yoshifumi Kado, Senior General Manager of Ion Exchange Membrane & Electrolysis System Division at Asahi Kasei. “By combining the expertise of Asahi Kasei, Nobian, Furuya Metal, and Mastermelt, we will be able to garner even more value from the important precious metals used in electrolyzer technology while transforming sustainability goals into practical, scalable outcomes.”