An important requirement for the integration of green hydrogen in the industrial environment is its large-scale availability. The SOE technology holds great promise for the production of hydrogen on an industrial scale. However, one of the critical steps in realizing the application potential of the SOE technology is increasing the size of the solid-oxide cell. This will contribute to reducing the complexity of the SOE system, thereby allowing a potential decrease in the system costs.

TNO manufactures solid-oxide cells with very thin electrolyte layers (3–5 microns), supported by a thicker electrode (300–500 microns). This guarantees high mechanical integrity. These cells are made by using a manufacturing process in which heat treatment at very high temperatures (>1300oC) is required. This heat treatment can lead to cell breakage and therefore a low manufacturing yield when the cell size is increased. TNO has optimized the cell production method by working on the heat treatment process, allowing the production of solid-oxide cells measuring 30 x 30 cm. This results in an increase in cell size by a factor of 4–5.

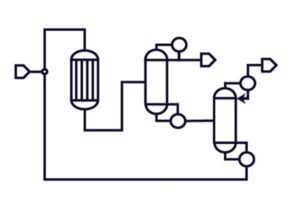

Another challenge is the testing of solid-oxide cells with these dimensions, for which TNO has developed and constructed a special stack test platform. The first hydrogen production tests with the new cells are said to have been very successful.

The demonstrated increase in cell dimensions and stack test platform are viewed as an important step in the realization of the application of the SOE technology for hydrogen production on an industrial scale.