Cooling capacity requirements in large-scale green hydrogen plants

In green hydrogen plants, whether using alkaline electrolysers (AEC) or proton exchange membrane electrolysers (PEM), a liquid is circulated over the electrolyser stack to produce hydrogen and oxygen. This process generates heat that must be effectively managed. However, there are more cooling points in the hydrogen production process. Alternating current (AC) is converted to direct current (DC), which releases heat. Other key areas include the formed oxygen and hydrogen, which are cooled before further purification. The deeper the gases are cooled, the more water is ‘knocked out’ by means of condensation, reducing the size required for the plant’s drying section. Further downstream, the hydrogen is compressed, which requires compression interstage and aftercoolers. A closed loop of water or a water/glycol mixture is used to cool the various coolers in the hydrogen production process.

For plants with an electrolyser capacity exceeding 100 MWe, a central cooling system is typically employed, with 30–45% of the electrolysing capacity managed by this system over its lifecycle (meaning 30–45 MWth to be dissipated).

Design considerations for large-scale green hydrogen plants

There are multiple solutions to cool the process fluid:

- Wet cooling towers: These are cost-effective, requiring less energy and space compared with other options. They can achieve a temperature approach of less than 5°C with a plate-and-frame heat exchanger for a closed-loop system. However, they result in a water loss of around 2%, which can be significant in regions with water scarcity and may affect local acceptance.

- Air fin coolers: When water is unavailable or highly restricted, air-cooled heat exchangers such as air fin coolers are used. Kelvion has developed specific finned tubes called Groovy-Fin® tubes, which enhance the heat exchange coefficient and allow a smaller temperature approach using the same surface area compared to AFCs equipped with standard tubes. However, despite their high performance, there are limitations in cooling the process fluid during hot weather or in harsh, arid environments when the Logarithmic Mean Temperature Difference (LMTD) is below 5°C.

Cascade Cooling reduces energy consumption and water waste

To optimise hydrogen production and minimise the levelised cost of hydrogen, a cooling system must be energy-efficient and use as little water as possible. This goal led to the development of the Cascade Cooling solution (see Figure 1).

During cooler to colder weather conditions, when ambient temperatures are significantly lower than the process fluid temperature, the system operates in a closed-loop mode with air fin coolers. This configuration reduces equipment size and the number of fan motors, which operate under variable frequency drives to minimise energy consumption.

In warmer to hotter weather conditions, air fin coolers operate at full capacity, with additional cooling provided by wet cooling towers. This setup, operating in a closed loop with a plate-and-frame heat exchanger, further lowers the process temperature while keeping water consumption to a minimum.

Cascade Cooling: a real case study in an arid and hot environment

A recent case study involved designing a large-scale green hydrogen production plant with electrolysis capacities of 2 x 200 MWe and 1 x 100 MWe. The project’s cooling requirements included:

- Located in a water-scarce area, making water consumption for cooling a concern and driving the project toward a dry-cooled system where possible.

- Cooling water required at 38°C, with peak summer temperatures reaching 39°C, necessitating some evaporative cooling.

- Below 28°C ambient temperatures outside peak summer months, allowing for dry air cooling and large air coolers. However, during peak summer months, temperatures exceed 28°C for up to 17 hours a day, requiring a solution for these peak hours.

One option being considered is a fogging system to reduce the ambient air temperature at the cooler inlets, ensuring the coolers remain effective during peak periods. This would require the fogging system to reduce the ambient air temperature from, say, 39°C to 28°C. The design wet-bulb temperature is 19°C, and simulations suggest that this level of temperature reduction is theoretically achievable.

Alternatively, a wet surface air cooler or a closed-loop cooling tower in series with the air cooler could be used in peak conditions through Kelvion’s Cascade Cooling solution.

The main technical drivers to be considered, in order of preference, are:

- Minimising water consumption due to the scarcity of water resource.

- Minimising electrical consumption.

- Minimising the plot space required for cooling equipment.

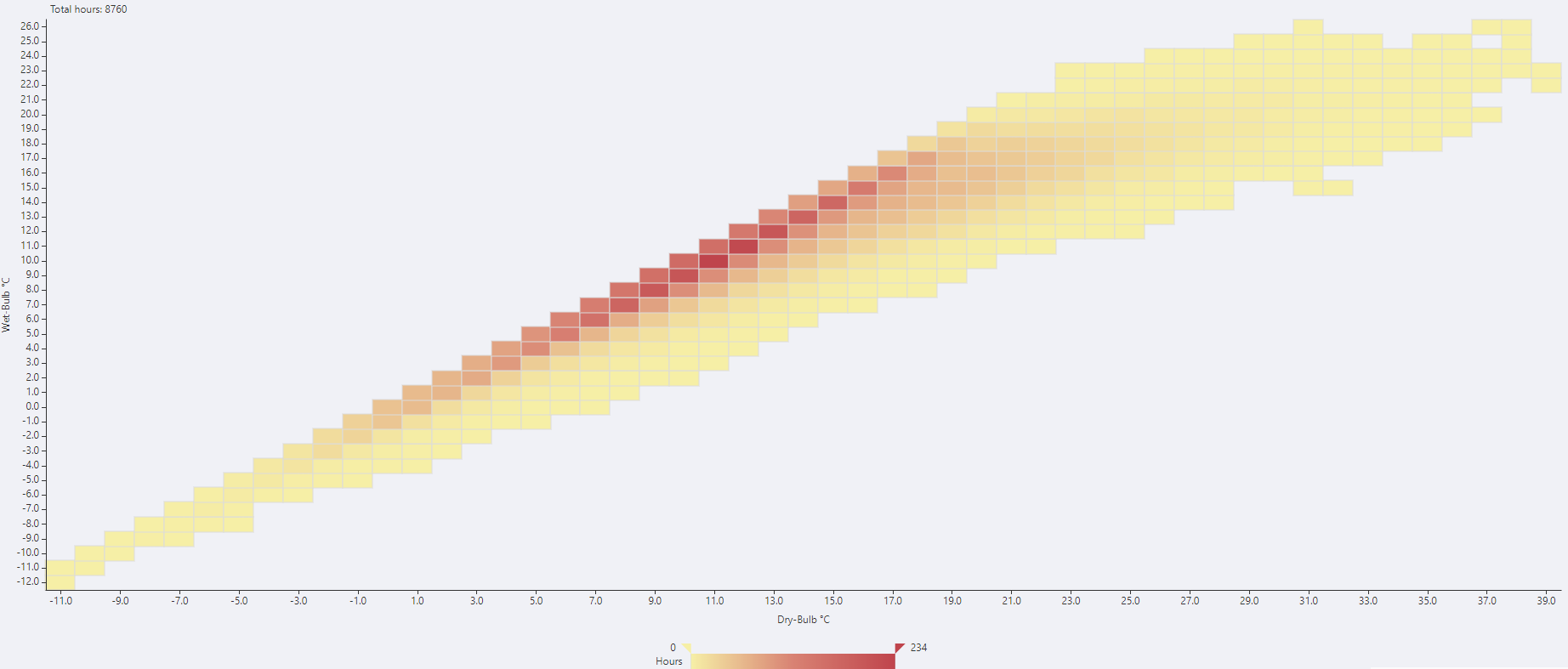

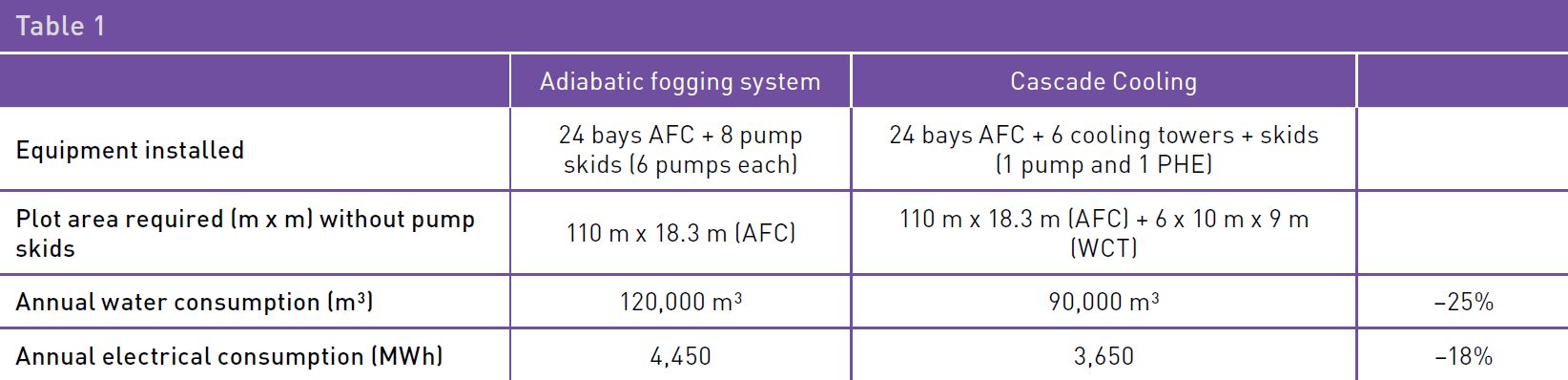

Using an ASHRAE database, which provides location-specific annual weather data, including dry-bulb and wet-bulb temperatures throughout the year and the corresponding number of hours (see Figure 2), Kelvion has developed a comparison table (see Table 1). This table contrasts a fogging system (adiabatic solution) with Cascade Cooling for a 200-MWe electrolysis capacity train.

Although Cascade Cooling requires more plot space, it offers significant savings in water and energy, thus lowering operational costs. If additional plot space is available, further improvements can be made by adjusting the switching point for Cascade Cooling. This adjustment leverages the efficiency of Groovy tubes to achieve a lower temperature approach between the dry ambient air and the outlet process temperature during the so-called winter period. Table 2 compares the Cascade Cooling solution with the switching point set at 28°C in dry ambient air to a configuration with the switching point set at 30°C.

Conclusion

Kelvion’s Cascade Cooling solution offers a modular and flexible approach to optimising cooling systems for large-scale green hydrogen plants. By taking into account environmental conditions, process temperatures, ambient conditions, available plot space, water scarcity, and energy costs, Kelvion can tailor the optimal cooling solution for each project. Cascade Cooling is designed to support various development phases, ensuring efficient and effective cooling across different stages of a large-scale green hydrogen project, starting from 100/200 MW in the initial phase and scaling up to gigawatts. Close collaboration with plant operators early on is key to enabling proper project design and optimisation.