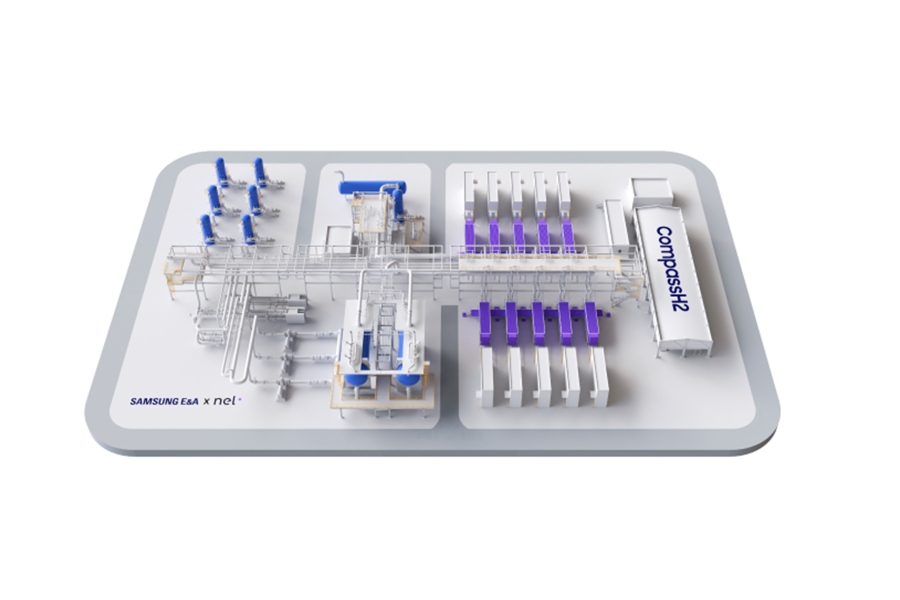

Air Liquide starts industrial-scale ammonia cracking pilot in Belgium

Air Liquide has begun operating a 30 t/day ammonia-cracking pilot unit in Antwerp–Bruges, Belgium – an important step toward enabling long-distance hydrogen transport and supporting emerging low-carbon supply chains.