This contract marks a significant milestone in Hystar’s expansion efforts and will encompass detailed planning and design. The new production line will significantly improve efficiency, increasing production capacity beyond the current 100 MW.

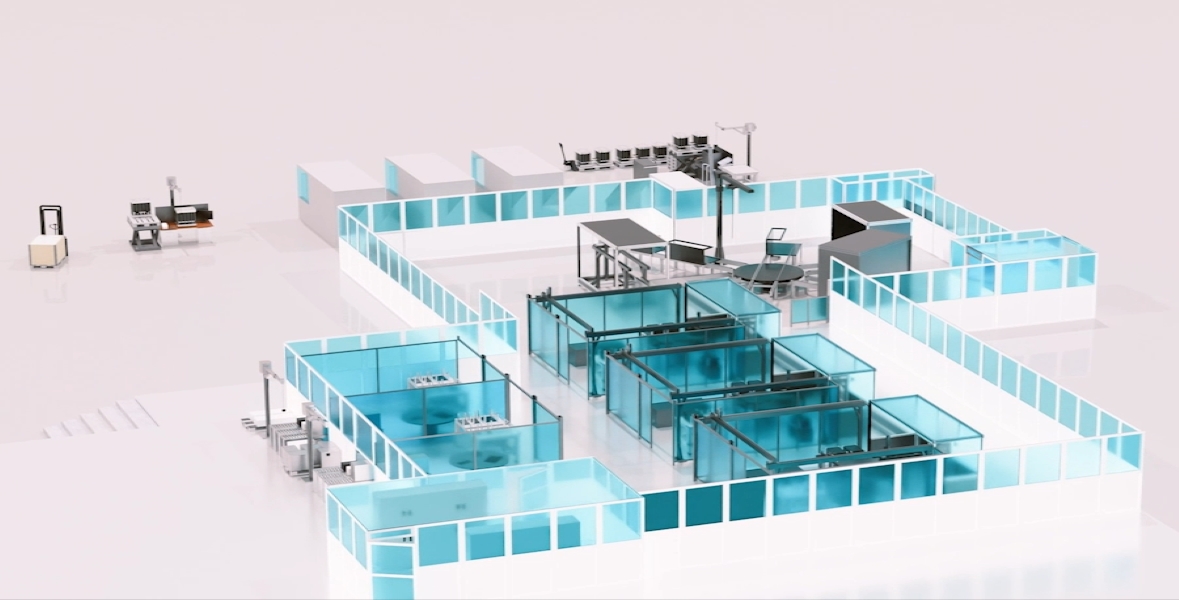

Uniquely for a GW electrolyser factory, the total footprint required is only 2,500 m², including stack assembly, quality control, and testing. The stack components are supplied by strategic suppliers from an established, high-volume supply chain. Utilising this existing supply chain allows Hystar to quickly scale up production capacity.

Fredrik Mowill, CEO of Hystar, commented: “Implementing our automated GW factory further strengthens Hystar’s ability to deliver competitive and efficient solutions to our customers for large-scale green hydrogen projects. We look forward to working closely with thyssenkrupp on this state-of-the-art automated production line, as we support the global energy transition.”

Michael Menneking, CEO of thyssenkrupp Automation Engineering, said: “We are very pleased that Hystar has placed its trust in us to cooperate in the planning of its factory. Our solutions will support Hystar’s journey to become a major player in the hydrogen industry.”