This investment will enable Element to meet the growing demand from customers transitioning to cleaner energy solutions and incorporating hydrogen in various product life cycles and systems.

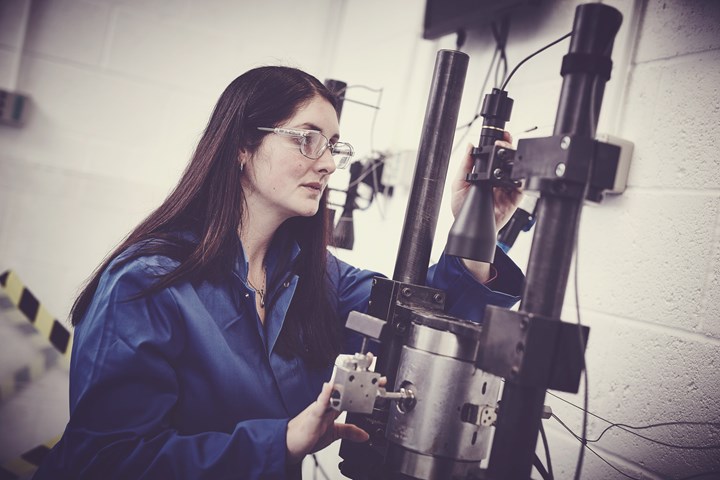

To bolster its capabilities, Element has developed specialized static and dynamic fracture mechanics equipment for its laboratories in the UK and Europe. This equipment enables hydrogen testing at pressures of up to 100 barg, frequencies below 1 Hz, and at cryogenic temperatures of up to -269°C, in a variety of test frame configurations. Positioned to serve the UK and European markets, these capabilities support global pipeline infrastructures during the energy transition, helping to understand fracture mechanics and hydrogen’s impact. The equipment will be used to assess hydrogen infrastructure and storage systems under varying in-situ

At Element’s Malvern, UK facility, 11 chambers conduct Electro Magnetic Compatibility (EMC) testing, ensuring the seamless operation of complex electronic components in modern vehicles. Recently, Element has upgraded its large equipment chamber with safety systems to test hydrogen-fueled vehicles and other equipment utilizing hydrogen as fuel, catering to customers entering this emerging market.

Element’s recent acquisition of Filton Systems Engineering (FSE), an aerospace engineering and testing services business, further enhances and complements these hydrogen-related offerings. Filton, with its team of 50 experts, brings extensive expertise in gaseous and liquid hydrogen, supported by a dedicated facility in Kemble, UK, featuring an in-house-designed liquefaction plant. This complements the acquisition of NTS Laboratories in the US last year, which has a dedicated hydrogen facility in San Bernardino, California that was previously used to support the space market with fluid flows and liquid hydrogen.

A dedicated hydrogen team has been established at Element, comprising experts in fuel cells, infrastructure, electrolysers, cryogenics, process, and functional safety. Working across a variety of market sectors for hydrogen, they are situated to coordinate services across Element’s laboratories worldwide. This team, along with the skills and capabilities of FSE, forms a wealth of knowledge and experience that can be applied to customer projects related to hydrogen, carbon capture, and infrastructure transition – across the full value chain and product life cycles.

Mark Eldridge, Director of Hydrogen at Element, said: “As hydrogen takes center stage in the global clean energy market, the materials and infrastructure involved present new challenges and contexts for use. Our recent equipment investments position us as Europe’s largest capacity for fracture mechanics testing in the hydrogen sector, with expertise in gaseous and cryogenic liquids. With our deep expertise in materials science, corrosion, coatings, and electrochemistry, we offer state-of-the-art testing, certification, and consulting services for various aspects of hydrogen-related technologies. Coupled with our significant digital engineering expertise, these services expedite time-to-market, crucial in achieving stringent net-zero targets.”