Shaping the future faster and more efficiently

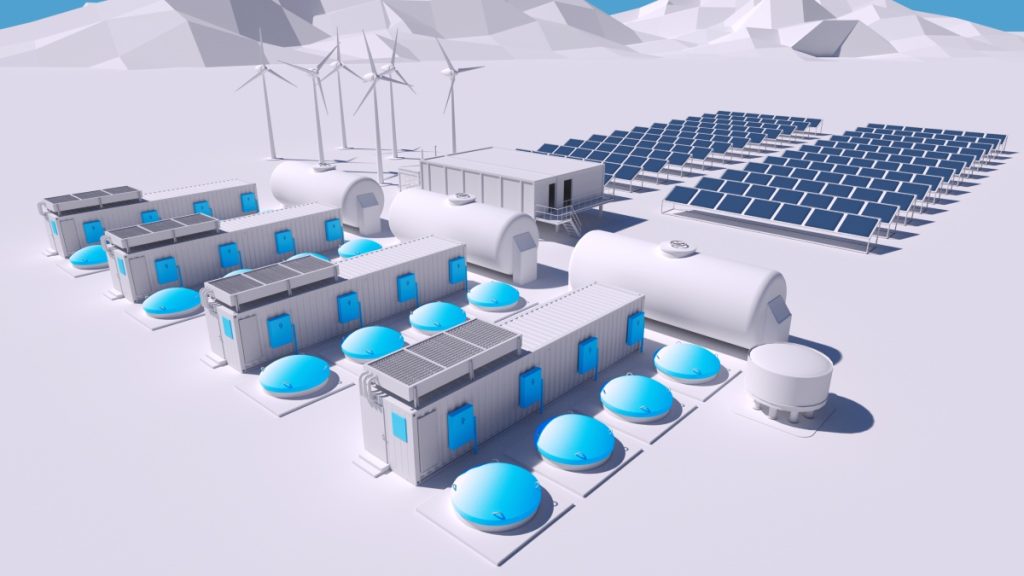

Green hydrogen and Power-to-X technologies are crucial for decarbonizing the industry. However, fragmented software ecosystems and document-based workflows impede progress toward fully digitalized processes and plants. Many companies are struggling with outdated tool landscapes, which often lead to error-prone and slow internal processes. While younger companies sometimes struggle with the complexity of plant engineering, established players often try to use existing and sometimes inappropriate tool chains to meet the market demands. Fragmented software tools and manual data transfers hinder rapid development cycles due to inconsistent data. A fundamental shift to centralized data models is crucial for success in these growing markets. A consistently data-driven platform is just as essential for OEMs, plant engineers, contractors, engineering companies, and systems integrators as it is for operators of new plants.

Data-centric and modular engineering

Engineering Base provides a centralized and object-oriented data model that integrates all engineering phases and disciplines. This facilitates simultaneous, interdisciplinary collaboration, eliminating errors such as duplicate entries or manual data transfers.

Standardization and modularization in particular are key building blocks when designing electrolyzers – on the one hand, to shorten project lead times and generate high-quality data for subsequent operational use, and on the other hand, to reduce the production costs of (green) hydrogen.

The principle benefits at a glance:

1. Rapid scalability through modular planning

- Highly standardized modules: Engineering Base allows you to work with predefined, function-oriented assemblies that can be simply ‘clicked together’ and scaled up.

- Numbering up instead of developing from scratch: Plants can be planned and completed faster by reusing tested and approved modules.

- Improved efficiency: Using standard modules can cover up to 90% of the planning work.

2. Streamlined processes for shorter project times

- Time savings: Any changes in the plant model are automatically visible in all other affected areas, eliminating the need for consultation and rework.

- Collaboration: Teams work simultaneously and in an agile way on a shared platform – from the concept phase through to commissioning.

- Cost reduction: Automated processes and consistent data allow more efficient use of resources.

3. High data quality for sustainable operation

- Digital twin: Engineering Base creates end-to-end digital models of plants that can be used for their entire life cycle – from planning to maintenance.

- Continuous updating: Engineering Base Mobile View enables maintenance and service data to be updated easily and flexibly on a mobile device directly in the plant. Thanks to the markup function, information is seamlessly integrated into the digital twin and automatically transferred to the engineering team as tasks – meaning that data and documentation stay fully up-to-date and interconnected at all times.

- Reliability: The central data model minimizes errors and provides up-to-date and consistent information at all times.

The digital twin is the key

“A key advantage of Engineering Base is the ability to create digital twins during the planning phase,” emphasizes Dr. Henry Bloch, Head of Product Management at Aucotec. “These twins not only serve as accurate representations of the plants but can also be enriched with live and asset data throughout their lifecycle. This is the foundation for continuous optimization of plants and simplifies maintenance.” This opens up numerous applications, such as predictive maintenance, which ensures early error detection and reduces lifecycle costs, or efficient turnaround management, minimizing downtime through optimized maintenance cycles.

“In the field of hydrogen production, Engineering Base is revolutionizing the development of state-of-the-art electrolyzers as the platform seamlessly integrates modular structures into the digital twin, resulting in highly efficient engineering and flexibility,” continues Bloch. “This saves plant operators and electrolyzer manufacturers significant time and a considerable amount of work, resulting in huge cost savings. A standardized data model that maps devices, functions, locations, and their relationships across all project phases creates the ideal basis for agile teamwork, including automation and safety systems,” says Bloch.

Data centricity as a transformation milestone

An example of how Engineering Base can support customers is illustrated by the company Topsoe. The Danish market leader for catalysts and electrolysis technologies implemented its largest transformation project together with Aucotec and Engineering Base. Senior managers described the introduction of Engineering Base as a decisive milestone in their digital transformation, allowing them to work ‘truly’ data-driven for the first time. By switching to a centralized data model, planning times were drastically reduced – tasks that previously took six months now require only a few weeks. This enables significantly more projects to be executed in a shorter time frame.

Another reason Topsoe opted for Engineering Base was the minimal need for custom solutions. Instead, new developments were collaboratively created and are now standard in the Engineering Base licenses, benefiting all customers: for example, EBML for faster data exchange or the automatic data sheets from Asset 360 – both important efficiency drivers for EPCs, plant manufacturers, and operators. “Topsoe’s transformation process was demanding. Never before has so much expertise and knowledge been brought together. Everyone had to adapt, but now there is a unified ‘data home’ for all engineering tasks. This increases flexibility and saves enormous costs,” explains Niclas Meier, Global Account Manager at Aucotec.

Modularization enhances efficiency for hydrogen specialist

Sunfire, a leading hydrogen technology company based in Dresden, Germany, also decided on Engineering Base to unify its fragmented software landscape and establish efficient processes. The Aucotec platform supports Sunfire in developing highly standardized modules that can be easily scaled. Plants are efficiently realized by multiplying these modules. Engineering Base’s object-oriented data model forms the foundation for much more efficient and agile plant development as well as clear modular engineering.

“With Engineering Base, Sunfire reduces the risk of errors through consistent data and automated change management. This improves the quality of documentation,” says Meier. “The ability of Engineering Base to modularize across disciplines is a particular focus for Sunfire.” Sunfire employs highly standardized modules that can be ‘clicked together,’ scaling plants through module multiplication.

Aside from modularization, the overall package was convincing for the hydrogen specialist from Germany. In addition to seamless object orientation and clear navigation possibilities between disciplines, the functionalities of Engineering Base along the entire engineering process were compelling – from the FEED phase to process engineering and EMSR technology.

Trailblazer for the energy transition

Companies that standardize recurring plant components benefit enormously from modular designs: these shorten planning and design times and optimize their processes. Especially for companies that view their plants as products rather than projects – such as electrolyzer planners – modularization offers decisive advantages.

For operators of these plants, modularization plays a secondary role. Nevertheless, operators also benefit greatly from a digital twin that provides reliable as-built documentation and an interdisciplinary plant model. Engineering Base enables this through direct development within the system or through integration and digital enhancement of existing data. The digital twin always remains up-to-date, allowing both manufacturers and operators of plants to focus more on essentials: building better plants faster and making more hydrogen-ready facilities operational with green hydrogen.

Key technology for the potential of green energy

With Engineering Base, Aucotec positions itself as a leading partner in the Power-to-X and hydrogen industries. The platform combines data centricity, modularization, and digital twins, enabling companies to achieve not only significantly shorter development times but also groundbreaking scalability and efficiency. Aucotec provides the key technology to fully unlock the potential of green energy and actively drive the transition to a sustainable future.

Last but not least, the Power-to-X and hydrogen industries are still at the development stage and face the challenge of creating sustainable and scalable structures. For young industries, it is crucial to rely on structured and data-driven processes early to remain competitive in the long term. Data forms the basis for innovative business models like predictive maintenance, AI-supported analyses, precise lifecycle cost calculations, and utilization forecasts. With its structured data, Engineering Base provides a future-proof foundation for efficiently tapping into these potentials and advancing the industry.

About Aucotec AG

Aucotec AG has almost 40 years’ experience in the development of engineering software designed for use throughout the life cycle of machinery, plant equipment, and mobile systems. Solutions range from flow diagrams and process-control/electrical technology for large-scale plant systems to modular on-board power supply units designed for the automotive industry. Software supplied by Aucotec is currently in operation throughout the world. In addition to the headquarters near Hanover, the Aucotec Group includes six other locations in Germany as well as subsidiaries in China, India, Malaysia, South Korea, the Netherlands, France, Italy, Austria, Poland, Sweden, Norway, and the USA. What is more, a global partner network ensures local support all over the world.