By David Bentley, CEO of Ardent Underground

Traditionally, and for the most part still today, hydrogen is produced by steam methane reforming which generally uses natural gas as feedstock. The bulk of hydrogen is used for ammonia synthesis, oil refining and other chemical processes. The input energy and feedstock to create grey hydrogen are available for continuous operation. The end-use operations are also closely integrated with the hydrogen production and operate simultaneously. This has meant that large-scale storage of hydrogen has not been required.

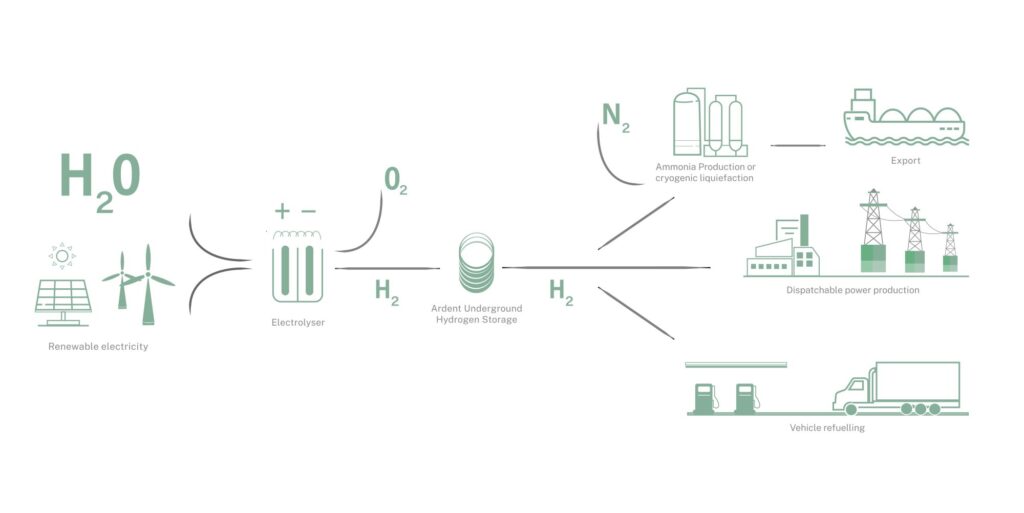

As the world embraces clean energy technologies, green hydrogen is likely to initially displace existing production of grey hydrogen and then provide a solution for hard-to-abate sectors such as heavy mobility and steelmaking as well as to become a vector or precursor element to carry renewable energy exports. Green hydrogen is produced by using renewable energy to power an electrolyser which produces hydrogen from water. The most prevalent and lowest-cost sources of renewable energy have intermittent and variable production, yet consumers and industry demand continuous, reliable, and dependable energy sources (see Figure 1).

Energy storage is therefore an essential element in the renewable energy value chain, decoupling renewable energy production from the demand for dependable and reliable energy. Storing renewable electricity to make hydrogen is many times more expensive than storing hydrogen.

Hydrogen storage

Hydrogen is the lightest element and has very low volumetric energy density at atmospheric conditions. To store meaningful amounts of hydrogen, its volumetric energy density must be increased either by compression or by reducing its temperature to form liquid hydrogen at -253°C or combined in chemical form.

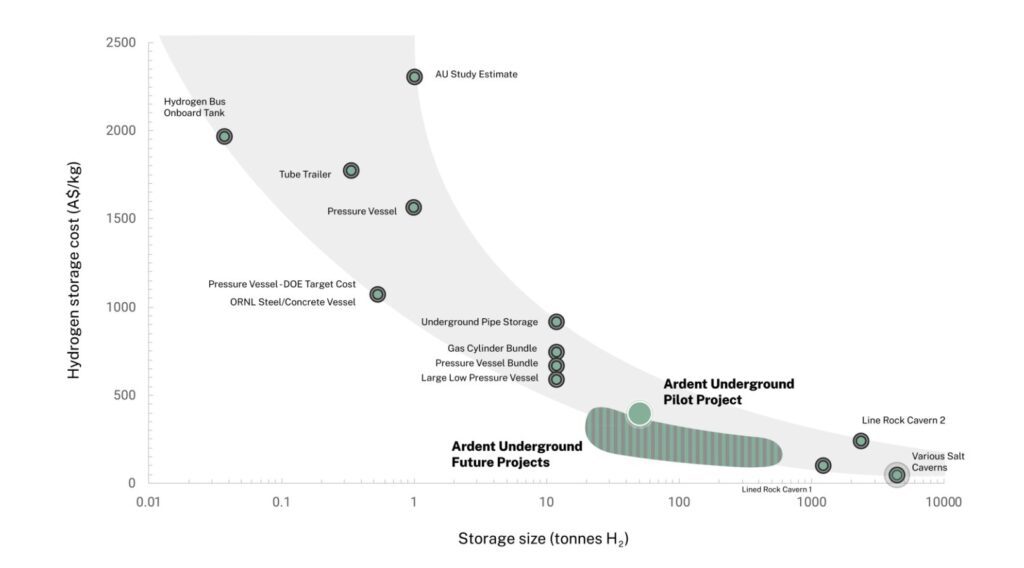

Steel pressure vessels are the most obvious solution, high-pressure composite vessels have been developed to reduce weight, and a labyrinth of pressure piping is technically feasible. A range of chemical processes are also at various stages of development but lack scale. On a large scale, solution-mined salt caverns and lined rock caverns have been proven but are very site dependant. Use of depleted gas wells or aquifer storage is contemplated but challenged by contamination issues and the volume of gas that must remain in storage (cushion gas).

In terms of specific cost per unit of storage capacity, large-scale solutions are more cost effective than the small vessels. There is a large gap in storage technologies between 10 and 2,000 tonnes as depicted in Figure 2. It is this gap that Ardent Underground addresses.

Hydrogen shaft storage

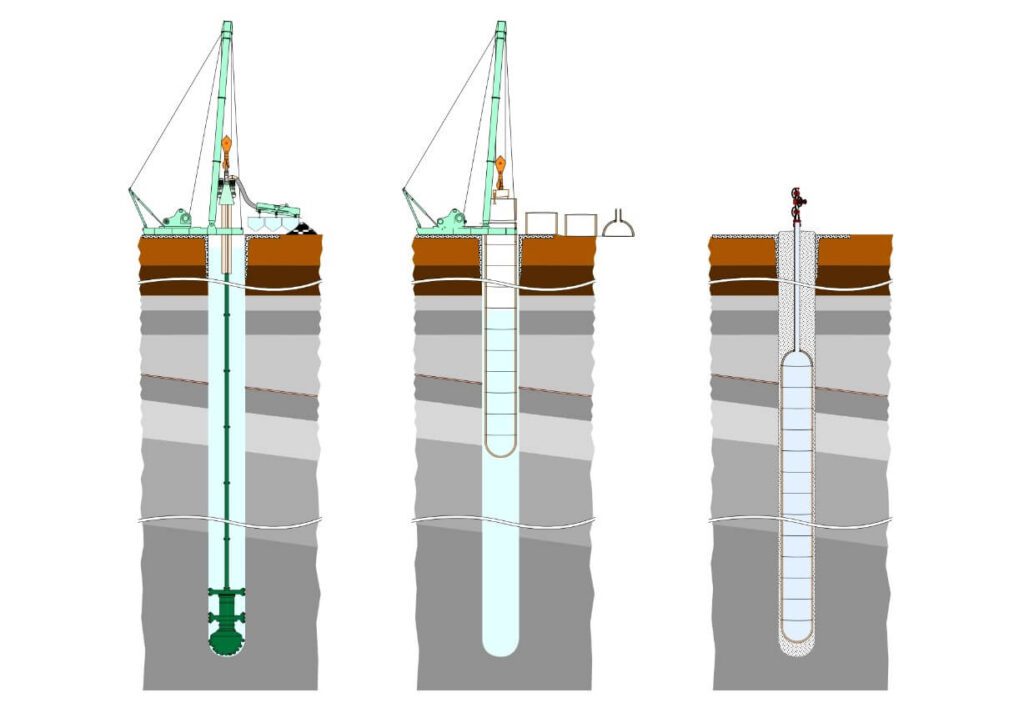

Ardent Underground has developed a solution that addresses the large gap in hydrogen storage capacity by providing a low-cost alternative that matches the requirements of any green hydrogen application. Ardent’s vertical-shaft hydrogen storage system utilises established vertical blind bore shaft excavation and lining technology and adapts a meticulously designed internal liner that prevents hydrogen from escaping while transferring the pressure forces of the compressed hydrogen to the surrounding rock (see Figures 3 and 4).

This unique design eliminates the need for costly high-strength materials that would otherwise be required for aboveground storage vessels. The design emulates that of a lined rock cavern, with the advantage of being entirely constructed from the surface and being economical for single-shaft projects between 10 and 500 tonne of compressed hydrogen gas storage. Multiple shafts can be constructed on the same site to accommodate larger storage requirements.

Is it safe?

Storing hydrogen underground offers numerous safety benefits to aboveground storage systems. The most obvious of these is that most incidents involving compressed gas storage are caused by interference with the storage vessel. This interference can take several forms such as accidental impact with a vehicle or excavating equipment, malicious intent, vandalism, or terrorism. The vertical-shaft storage system safely locks hydrogen deep underground, making any accidental or other interference impossible. The footprint of aboveground facilities is minimal, so they are much easier to protect from interference, eliminating this problem by design. The connection to the surface infrastructure is via adapted wellhead systems from the gas industry and incorporates automatic blowout prevention devices that keep the hydrogen contained in the event of damage to aboveground piping.

Another important safety aspect is that for hydrogen to deflagrate or detonate both an oxidant and an ignition source are required. Ignition of hydrogen requires a very small energy source (0.017 mJ in air) which can occur unexpectedly. It is therefore essential that an oxidant such as air is not present with stored hydrogen. All aboveground storage vessels are surrounded by air which can support a deflagration or detonation. By contrast, the Ardent Underground storage is purged with nitrogen prior to introducing hydrogen, and the storage is surrounded by solid rock, meaning that there is no opportunity for air to come into contact with hydrogen.

Simple, practical solution

As the world transitions to renewable energy, hydrogen will have an important role to play in addressing those segments of the market that cannot be easily electrified as well as an energy storage/transfer vector. Since existing storage options are constrained by size limitations, hydrogen storage in the 10s to 100s of tonnes will be key to enabling the migration to renewable energy. The vertical-shaft storage system offers key advantages addressing this range, with low environmental and visual impact. Furthermore, it offers a much safer alternative and responds to the scale needed to support the emerging green hydrogen industry.

Storage case study

A recent study1 investigated the engineering and economic feasibility of constructing a renewable hydrogen facility for production of feedstock for an ammonium-nitrate production plant in Australia that currently relies on grey hydrogen. One of the critical elements of this study was to demonstrate how renewable energy from solar resources could be used to ensure the continuous supply of reliable hydrogen feedstock. The report concluded that due to the characteristics of the natural landscape in the region, pumped hydro energy storage was not feasible and energy storage in batteries was more than seven times the cost of storing green hydrogen to meet the operational requirements of the plant.

The authors investigated compressed hydrogen storage and concluded that the required 54t of hydrogen could be stored at 250 bar (25 MPa). Storage in a salt deposit was not feasible as there were no salt deposits in the region and this type of storage is only viable at a much larger scale. Similarly, a lined rock cavern would not be viable unless the storage required was many times larger than that needed for this project.

The solution selected was to use composite pressure vessels installed within 20’ ISO shipping container frames. A total of 278 of such containers would be needed to achieve the required storage capacity. They would be installed at the site to be connected with high-pressure piping, valves and safety devices. The site would require some 21,000 m2 of land surrounded by a blast wall measuring 728 meters in length and 4 meters in height. The selected solution highlights a variety of problems associated with aboveground hydrogen storage systems, namely that they have a high specific cost per unit of hydrogen storage, pose a significant safety risk, and are limited in storage capacity.

By contrast, the Ardent Underground solution could safely provide the 54t of storage in a single pressurised vertical shaft, occupying just a few square metres, and at 1/3 of the cost.

References

1 DNM Renewable Hydrogen Feasibility Study by ANT Energy Solutions & Dyna Nobel Moranbah, with support from the Australian Renewable Energy Agency (ARENA).