Introduction to Iron Power

In 2015, a meeting for a research program into the combustion behavior of powders under zero-gravity conditions (Perwaves) was held at the European Space Agency (ESA) campus. This research program was coordinated by Philip de Goey from Eindhoven University of Technology and Jeff Bergthorson from McGill University. Here, a concept was conceived that would transcend the boundaries of space exploration and catalyze a revolution in terrestrial energy storage – Iron Power.

Traditionally, metal fuels had been stalwarts in space travel, serving mainly as solid rocket propellants since the 1970s. However, it was in this ESA meeting that the seeds were sown to harness the potential of metal fuels, particularly iron powder, in a circular manner for applications on Earth. The vision was clear: to create a method that could compactly and safely store energy, laying the foundation for a sustainable future.

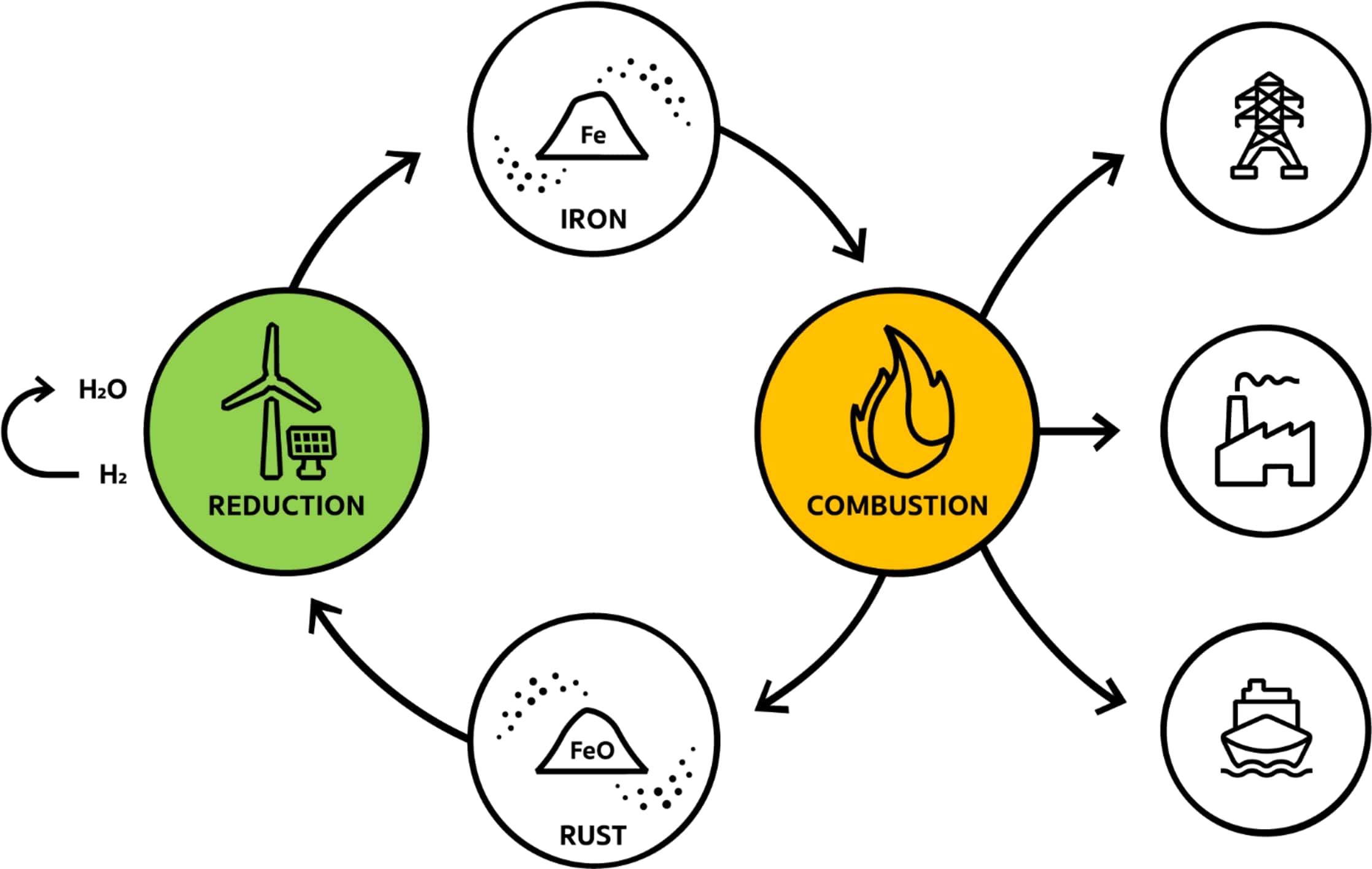

Iron Power, the brainchild of this ESA collaboration, introduced a novel approach to energy storage. The process begins with the controlled combustion of iron powder, yielding heat that can be utilized for various applications. What sets Iron Power apart is its regenerative capability—using hydrogen derived from abundant solar and wind energy sources, the iron oxide produced during combustion is seamlessly converted back to iron powder.

Advantages of Iron Power

The significance of this technology lies not only in its carbon-free combustion but also in its potential to offer a low-cost, safe, and environmentally friendly solution for storing substantial amounts of energy. Iron Power emerges as a beacon in the energy transition, particularly in industries reliant on intensive heat processes.

The combustion of iron powder stands out due to its low environmental impact, boasting minimal NOx and particle emissions. At approximately 2000°C, the combustion temperature aligns with that of fossil fuels, making it relatively easy to integrate into existing infrastructure.

Furthermore, at 25 MJ/L the volumetric energy density of iron powder surpasses that of conventional energy carriers like ammonia and compressed hydrogen, presenting a compelling case for its widespread adoption. This unique combination of clean combustion, high energy density, and cost competitiveness positions Iron Power as a transformative force in the sustainable energy landscape.

Potential of Iron Power

Approximately 65% of industrial energy consumption is allocated to heating processes, making electrification a challenging and sometimes suboptimal solution. This is particularly true for decentralized production facilities that may lack access to planned hydrogen infrastructure. Iron Power emerges as a promising alternative for decarbonization in such scenarios, offering easy transport and storage capabilities at decentralized sites.

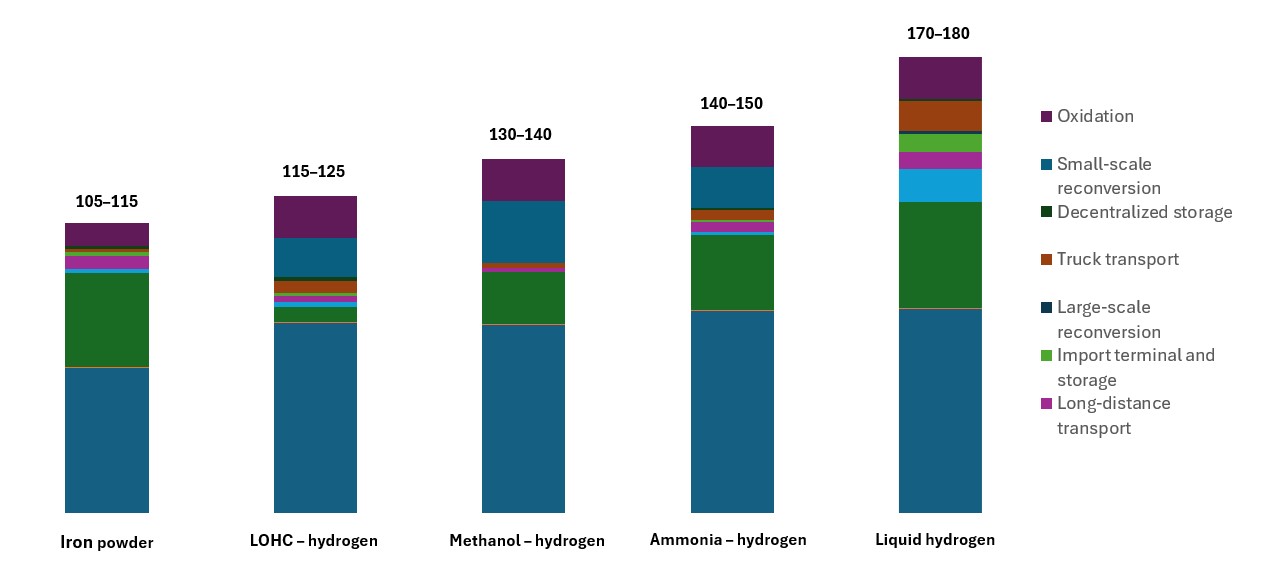

A study by Roland Berger evaluated the Levelized Cost of Energy (LCOE) for various green energy carriers, assuming hydrogen production in the Middle East due to its anticipated low-cost and high-volume production. The analysis revealed Iron Power’s strong cost competitiveness, attributed to minimal boil-off losses during transport and its direct usability without the need for reconversion, highlighting its potential as a key player in the transition to sustainable energy systems.

From research to commercial demonstration

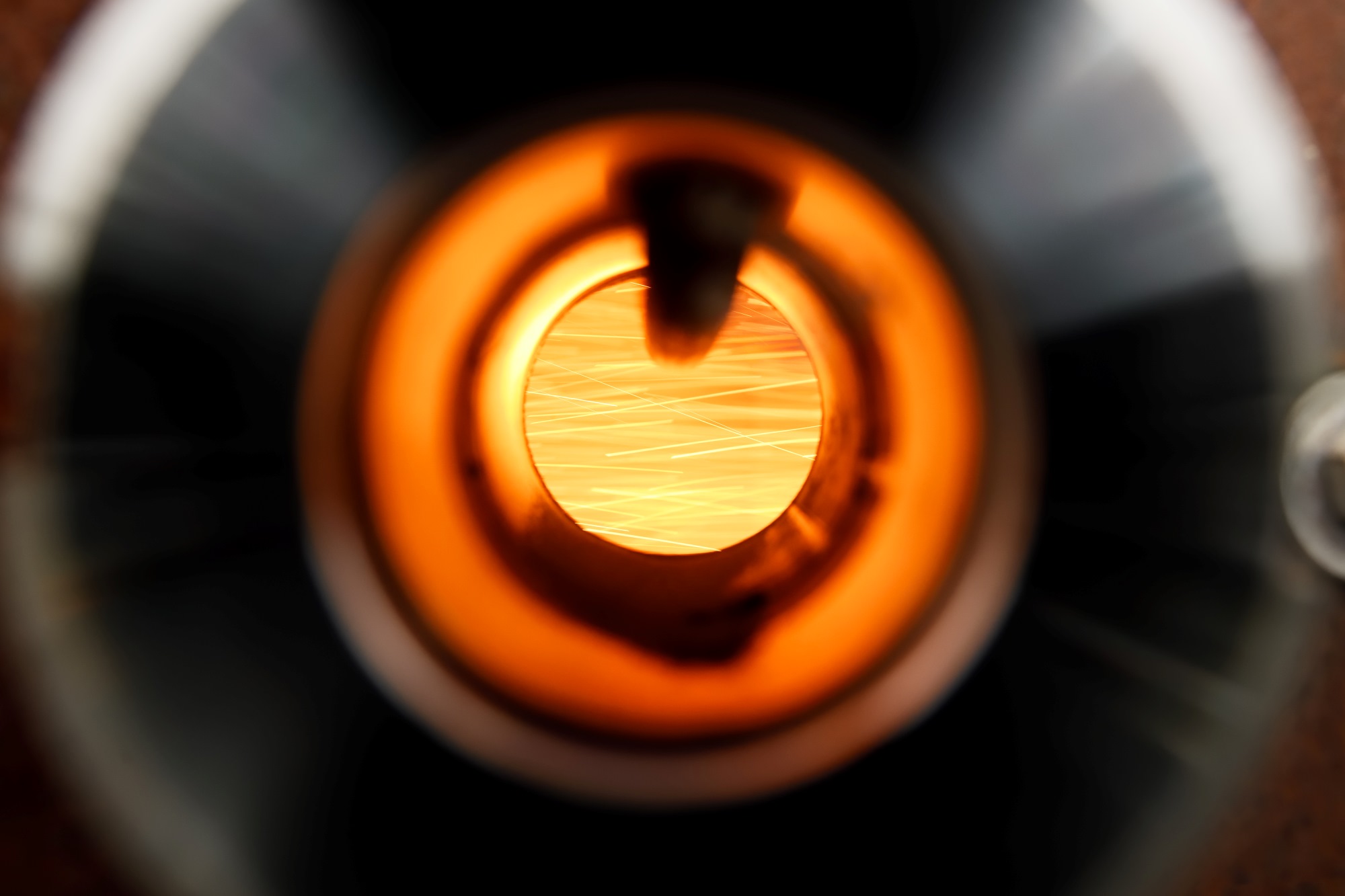

The inception of Iron Power at ESA laid the groundwork for a journey that would span years of research, development, and real-world demonstrations. In the laboratories of Eindhoven University of Technology (TU/e), Iron Power transitioned from conceptualization to tangible reality. The pioneering work from a dedicated group of students and researchers within the Mechanical Engineering department of TU/e, led by Professor Philip de Goey, culminated in 2017 with the creation of the first iron powder flame – a milestone that marked the initiation of a transformative journey.

First industrial demonstration

Recognition of the potential of Iron Power also led to the formation of Student Team Solid. This team consists of about 30 students from different disciplines who work on scaling up the Iron Power technology as a voluntary extracurricular activity alongside their studies. Supported by TU/e and Metalot, they worked on the first industrial-scale Iron Power system. In 2020, they unveiled the MP100, a 100-kW iron combustion system. This system, a testament to the collaborative spirit between academia and students (TU/e, Team Solid, Metalot, EM Group, Romico, and HeatPower), had its first demonstration at the Swinkels brewery. Here, iron powder was combusted, and the heat released during combustion was used to generate steam. This steam was utilized in the beer brewing process, resulting in zero CO₂ impact.

The successful MP100 demonstration sparked the birth of startups in Eindhoven dedicated to commercializing this groundbreaking technology. Two startups, RIFT and Iron+, emerged to harness the commercial potential of Iron Power. These ventures, born out of the ecosystem nurtured by Metalot, symbolized a transition from theoretical possibilities to tangible, scalable solutions.

First megawatt

After the demonstration of the MP100, it was decided to further improve this system. A redesign of the combustion chamber allowed for experimentation at higher power throughput. Thorough testing of the MP200, the upgraded system operating at 200 kW, was conducted in the Metalot Future Energy Lab facility. Subsequent modifications resulted in the MP500, a 500-kW powerhouse showcased again at the Swinkels brewery in the summer of 2023. Simultaneously, RIFT developed a 1-MW pilot plant in which they provided heat to 500 households in Helmond, showcasing the adaptability of Iron Power beyond industrial settings. This initiative mirrored the ecosystem’s commitment to exploring diverse applications and making a tangible impact on local communities.

A growing community

As the Iron Power technology gains international momentum, we have seen several international startups emerge in France, Canada, and Australia (Fenix, GH Power, FeX, Altiro, and Ferron Energy). The ecosystem nurtured by Metalot has become a hotbed of innovation, with multiple startups exploring diverse applications of Iron Power. This internationalization underscored the universal applicability and scalability of Iron Power as a revolutionary energy storage solution.

Current projects and future challenges

With the success of the MP500 demonstration and the pilot projects, the Iron Power ecosystem stands at the forefront of sustainable energy solutions. Ongoing projects and ambitious initiatives define the current landscape, outlining the trajectory for Iron Power in the years to come.

One of the leading projects involves substantiating the cyclicity of iron powder on an industrial scale. While lab-scale tests have shown good results, the shift to larger-scale applications introduces complexities that demand meticulous exploration. The challenge lies in the reduction step with hydrogen, where slower timescales necessitate innovative approaches. This process has many similarities with the reduction process currently being developed by the green steel industry.

The growing demand for iron powder prompts exploration into alternative production methods. Conventional approaches, such as atomization of liquid iron, pose economic and energy-intensive challenges. The ecosystem is actively investigating different sources for iron powder to meet the surging market demand, such as ground Direct Reduced Iron (DRI). Another crucial component in the Iron Power ecosystem is hydrogen. Heralded as a cornerstone of the energy transition, hydrogen faces challenges in storage and transportation. Iron Power emerges as a transformative solution, leveraging its capacity to store energy from hydrogen in a compact and efficient manner. By overcoming the hurdles associated with hydrogen storage, Iron Power catalyzes the adoption of a hydrogen-based society. As a key component in the regeneration process, the cost of hydrogen significantly influences the overall economics of Iron Power. Ongoing efforts in the hydrogen sector and advancements in green hydrogen production are closely monitored, presenting opportunities and challenges for the Iron Power ecosystem.

As Iron Power continues to gain momentum, a nuanced analysis of its applicability in various industries becomes crucial. The predominant use of energy in industries is for heat, positioning Iron Power as a strategic player in addressing the heat-intensive demands of diverse sectors. The ongoing exploration of applications ensures that Iron Power aligns with industry-specific requirements, driving a targeted and effective energy transition.

* Opening photo by Bart van Overbeeke Photography