By Matjaž Matošec

Founded in 2020, Hystar is a young – yet quickly growing – enterprise. As a spin-off from SINTEF, Scandinavia’s largest independent research organisation, the company has a background of over 15 years of research into PEM technology, making its patented electrolysis process the fruit of thorough development work and testing. Born out of a desire to facilitate and accelerate the transition to a green future, Hystar has the vision and ambition to become one of the top electrolyser suppliers worldwide, setting new standards in terms of efficiency, scalability, and sustainability. To learn more about their technology and growth plans, we spoke to Jan Schmidt, Hystar’s project engineer.

Originally from Austria, Jan forms part of a 30-strong international team based in Høvik, just outside of Oslo. Having previously worked as a fuel cell development engineer for a global technology provider, his main responsibility at Hystar is the development of a modular approach for the company’s game-changing electrolyser.

Rethinking the electrolysis process

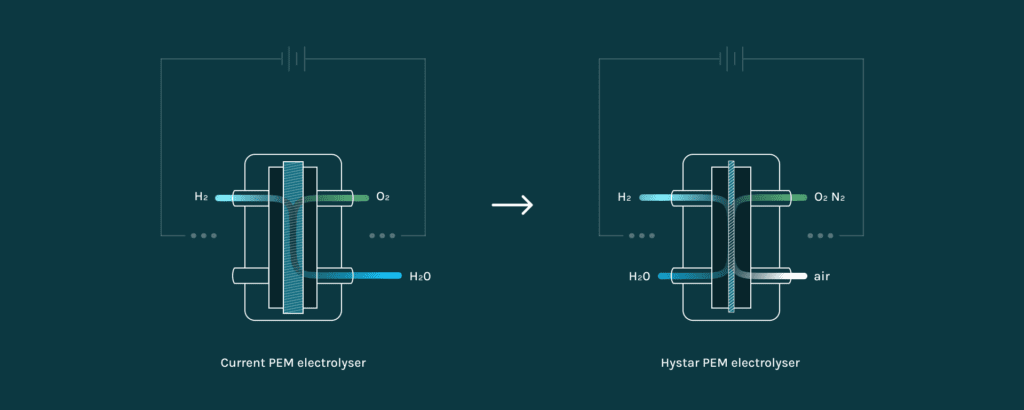

At the heart of Hystar’s patented technology is the operating principle of a PEM electrolyser. Traditionally in PEM electrolysis, water is fed into the anode chamber. By moving the water feed to the cathode side, Hystar has devised a process solution that offers an array of benefits. “If you find this solution simple, this is because it is simple, beautifully so,” says Jan.

“By changing the point of water supply to the cell, we have created conditions allowing us to reduce the membrane thickness by as much as 90% compared to conventional PEM electrolysers, which is remarkable. Hydrogen crossover to the oxygen-containing anode side is a major concern for all electrolysers, because the combination of the two gasses creates a potentially explosive environment. To prevent this crossover, all other PEM electrolyser manufacturers use a relatively thick membrane. While ensuring safety, however, this has a negative impact on the electrolyser efficiency since a thick membrane creates high electrical resistance. And the higher the resistance across the membrane, the lower the efficiency. Our solution, with a significantly thinner membrane, allows the water to travel from the cathode to the anode side, which creates the necessary conditions for the electrochemical splitting of water into hydrogen and oxygen. And by introducing another unique feature – the blowing of air into the freed-up anode chamber, our patented solution dilutes any crossover hydrogen, thereby eliminating the risk of forming a dangerous gas mixture.”

What is more, the ventilation rate can be adjusted, providing additional safety and operational advantages.

“For example, a membrane rupture or stack malfunction would normally trigger an emergency shutdown,” explains Jan. “In a Hystar system, however, we can immediately increase the air feed to stabilise the electrolyser and allow it to continue running safely until the malfunctioning component can be replaced.”

Scalability

Besides efficiency and safety gains, Hystar’s technology provides another crucial advantage: compactness. By using a thinner membrane, Hystar has managed to reduce the size of other system components, making them resemble those originally designed for fuel cells. In doing so, the company can piggyback on the development work done by the fuel cell industry as well as rely on its existing manufacturing capabilities.

“Our stack is designed and optimised for mass production,” explains Jan. “All our components are designed and developed in-house, in close collaboration with our high-quality suppliers around the globe.”

“Our stack is designed and optimised for mass production.”

In an ambitious plan to have a fully automated, gigawatt-scale assembly line in place by 2025, the company has launched a project aimed at developing the best approach to scalable, flexible, and quality-focused stack production. Dubbed ‘Autostack,’ the project gathers Hystar engineers and experts from three external partners. Semcon brings valuable experience from fuel cell design and manufacturing, Tronrud Engineering brings know-how in advanced engineering, while SINTEF Digital brings a holistic approach to the project, looking at the entirety of the supply chain and bringing expertise on modern manufacturing in high-cost countries.

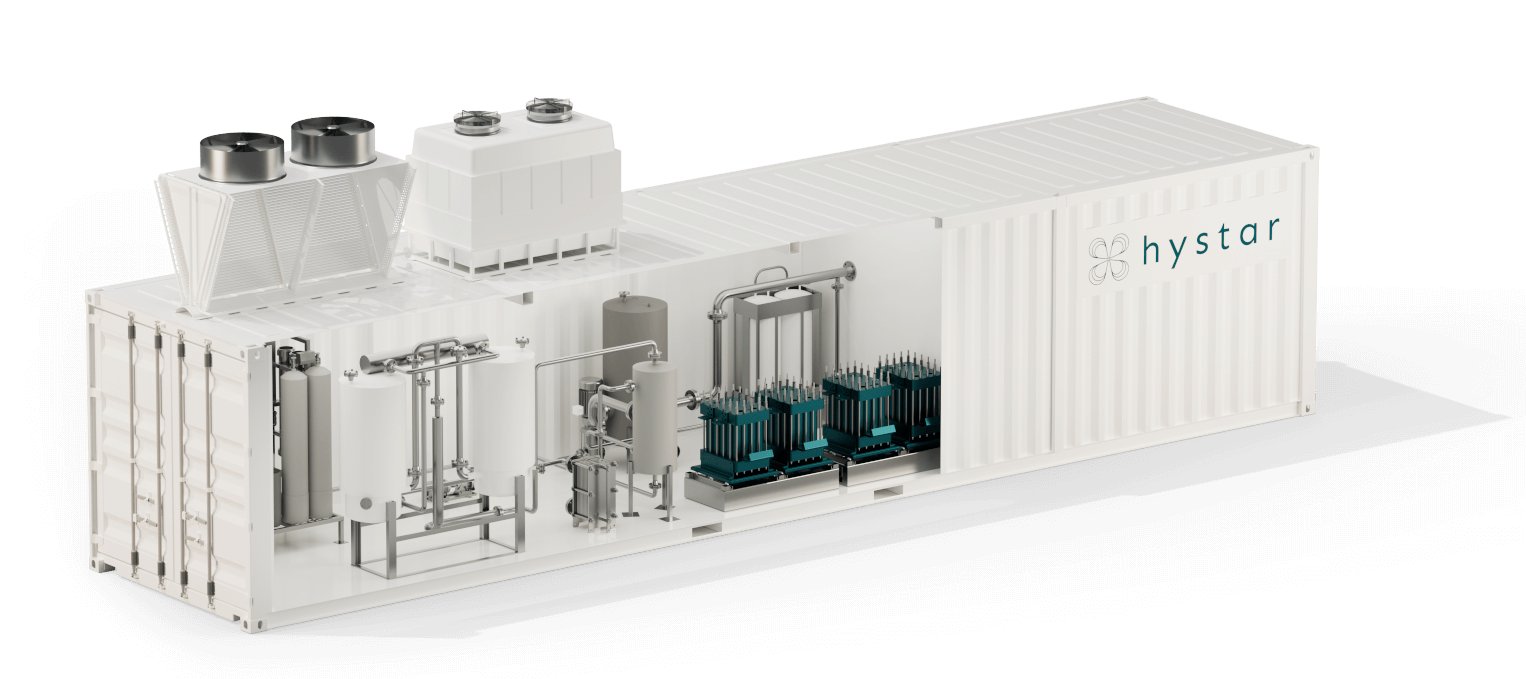

Containerised electrolyser

Despite being founded just over two years ago, Hystar is already taking orders from customers for its containerised, turnkey electrolyser solution, which is available in two main variants – Vega and Mira. Optimised for high efficiency, Vega has been designed for systems associated with high electricity consumption and costs, such as those found in heavy industry. By contrast, Mira is ideally suited for systems powered by intermittent energy sources and for customers looking to reduce capital investment costs compared to conventional PEM electrolysers. Both variants are available in the 1–6 MW range, with a lead time of 12–18 months.

In March 2022, the company, in partnership with Equinor and Gassco, launched a three-year project focused on gaining operational experience. In September, the HyPilot project was joined by another partner, Yara Clean Ammonia, the world’s largest ammonia distributor. As part of the project, Hystar will design and construct a containerised 1 MW electrolyser with a hydrogen production capacity of up to 500 kg/day. The electrolyser will be installed at Equinor’s K-lab facilities, close to the Gassco-operated Kårstø gas processing plant near Stavanger, Norway, and will run for a total of 10,000 hours, starting at the end of 2023. Being the first in-field installation of Hystar’s containerised electrolyser, the HyPilot project will see the system designed to suit variable production loads typically found in wind applications. Less variable production regimes will also be tested to provide data on the performance of Hystar’s electrolysers for industrial-scale hydrogen production.

Orion: large-scale, modular solution

Seeing the efforts to decarbonise hard-to-abate sectors as the main drivers of future demand for green hydrogen, Hystar is fully aware that quenching the thirst for hydrogen of industrial customers will require an electrolyser solution that can be easily scalable from 20 MW to 1 GW and beyond. Named Orion and described as a constellation of either Vega or Mira stacks (or a combination of the two), Hystar’s modular electrolyser concept provides exactly that.

“Unlike containerised electrolysers, which are standardised, ‘plug-and-play’ products, so to speak, large-scale plants typically require customised solutions,” explains Jan. “To avoid having to design every plant from scratch, we are busy developing a scalable electrolyser concept based on modules that can be multiplied to create a large green hydrogen plant of virtually any capacity. In an ideal world, we would be able to build large-scale electrolysers just like any Lego structure, so adding a given number of standardised building blocks, or modules, to reach the desired plant capacity and specifications. This is the idea behind the Orion concept: building large facilities using multiple stack modules and just one balance of plant. By achieving this, we will be able to reduce production costs, improve the quality of the product and shorten lead times because there will be no need to re-engineer again and again.”

Sustainability

Along with efficiency and scalability, sustainability is at the heart of Hystar’s endeavours, playing a key role not only in supplier management, but also process development. Committed to a circular economy and aware of the scarcity of catalytic materials used in PEM electrolysers, the company is determined to facilitate their reuse in every possible way they can. Jan elaborates: “Everything we do is done with sustainability in mind. As part of the Autostack project, for example, we are looking at how to design and build our stack in such a way that after the end of the product’s lifetime, all its recyclable parts can be recycled as easily as possible. In addition, we are exploring different options to reacquire end-of-life products from our customers as well as engaging with industry partners about the best recycling routes.

“Reaching for the stars, we believe in a bright future – for Hystar and our planet,” concludes Jan.

What’s in the name and logo?

The company name – Hystar – is inspired by the abundance of hydrogen in the universe. With the lightest of all elements being the main constituent of stars, the future of green hydrogen is seen by Hystar as being written in the stars.

The shape of the logo is inspired by a hydrogen density plot that represents how the electron of a hydrogen atom moves in orbit, capturing the dynamic and vibrant character of Hystar. Additionally, the logo has strong references to water, as the thin lines add a dynamic feeling, giving associations to water ripples, and each ‘petal’ (orbital) resembles the shape of a water droplet. The logo can also be seen as an ‘H’ for Hystar, or even as a clover leaf, representing sustainability.