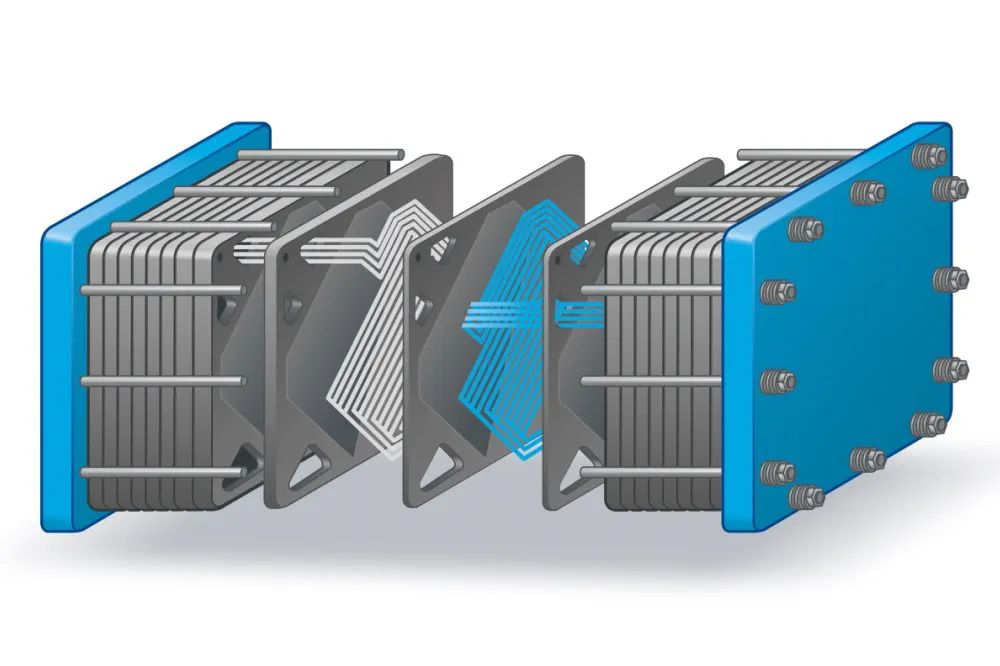

Freudenberg’s elastomeric gaskets are overmolded onto composite and metal electrolyzer stack plates in a four-step process. Stack plates are used to separate the cells in a stack assembly; a crucial component of the plates are gaskets which prevent the leakage of gas into other parts of the electrolyzer. The company is using a portfolio of proprietary rubber-based gasket materials, including EPDM and FKM formulas, to address the unique performance requirements and electro-chemistries found in different types of electrolyzers. In addition, Freudenberg has developed material-specific bonding agents that are applied between the gasket and plate materials to ensure the sealing function is optimized.

Extensive material testing, along with advanced injection molding techniques, enable the company to produce high-quality electrolyzer gasket-plate units that are easily transported to, and installed at, customers’ production sites.

“As manufacturing industries make strides in moving toward mass green hydrogen production, our ambitious goal is to support demand for high-capacity electrolyzer gaskets by 2023,” said Robert Lidster, Technical Director, Gaskets Division, Freudenberg Sealing Technologies. “For years we have been successfully sealing fuel cell systems. While these do not operate at the pressure and temperature extremes found in high-density electrolyzers, they have provided us with a complete understanding of what is required to seal these aggressive environments over a very long lifecycle. Our electrolyzer customers are benefitting from this expert knowledge.”

Freudenberg’s engineers are currently working on gasket integrated electrolyzer plates for polymer electrolyte membrane (PEM) and alkaline (AEL) electrolyzers. Due to the differences in the electrolyte materials used in these systems – PEM systems use a solid electrolyte membrane of Perfluorosulfonic acid (PFSA) polymers and AEL systems use a liquid electrolyte solution such as potassium hydroxide or sodium hydroxide and water – the facilities collaborate closely with customers to tailor gasket materials and adhesives for optimal performance in different types of electrolyzer systems. Concerns about pressure and temperature are not the only performance measures the engineers consider; corrosion resistance, stability, material breakdown and permeability are also closely matched to different electrolyzer environments. Here too, the company’s fuel cell expertise comes into play by allowing its scientists and chemists to reference performance and compatibility testing between its materials and the hydrogen environment found in these smaller systems.

Freudenberg is continuing its pursuit of innovative sealing solutions for more green power and transportation applications and is pursuing other rubber-coated metal components for electrolyzers and other alternate power systems.