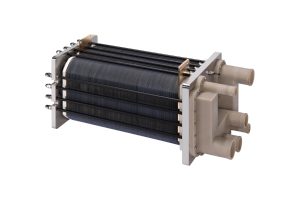

Construction of the 14,000 m² facility, which is being developed together with Maru Ehitus AS, started at the beginning of January 2024. The facility will deploy the latest technology, featuring customised, automated, and high-output production processes to enable mass manufacturing of solid oxide fuel cell and electrolyser cells and stacks.

Enn Õunpuu, CEO of Elcogen, commented: “We are glad to scale up our production capacity and we are proud that the new factory will be equipped with the latest available technology. This will significantly decrease environmental impact in terms of minimised air pollution, recaptured waste through a circular economy and use of residual energy from our process as well as self-produced renewable energy.”

Stefano Piscitelli, COO of Elcogen, added: “This new cutting-edge facility will boost our manufacturing capacity and generate efficiency gains leading to a remarkable 60% cost reduction. The scalability of our production technology will enable us to further optimise our cost structure and the factory will also serve as an industrial platform for our global expansion.”

Margo Dengo, CEO of Maru Ehitus, said: “As we in Maru Ehitus aim to build the tomorrow where we want to live, we are delighted to be a partner for Elcogen AS, who give their substantial contribution to a greener future. Our main focus is industrial real estate and the new production facility for Elcogen not only gives us opportunity to use our experience but is also an interesting challenge; the building is very complex, there are high demands from the process side and it uses several modern technologies, such as the re-use of excess heat.”