Powering heavy-duty vehicles, such as Class 8 semi-trucks, requires very energy-dense storage systems. While hydrogen is a promising fuel source difficult-to-decarbonize sectors such as heavy-duty mobility, hydrogen-storage technologies do not provide diesel-parity performance, as these compressed-hydrogen storage systems have limited energy density capacity. Cryo-compressed (Cc) hydrogen, which can support the highest hydrogen densities in a compact storage system, can overcome this challenge.

Storing hydrogen in this state provides much greater energy density than other competing hydrogen platforms: relative to liquid, 700-bar compressed hydrogen at ambient temperature, and 350-bar compressed hydrogen at ambient temperature, CcH2 offers an improvement of 27%, 77% and 165% greater hydrogen density, respectively.

For the last two years, researchers at Livermore’s Cryogenic Hydrogen Fueling Facility, with funding from Verne, have evaluated and tested Verne’s hydrogen-storage systems, successfully demonstrating a new advance in high-density hydrogen storage for heavy-duty vehicles.

“Past work at LLNL on cryo-compressed hydrogen storage has focused on the light-duty automotive sector. Storage systems for heavy-duty vehicles need to store an order of magnitude more hydrogen, greatly increasing the cost and time required for testing,” said Nick Killingsworth, principal investigator and mechanical engineer at the Laboratory.

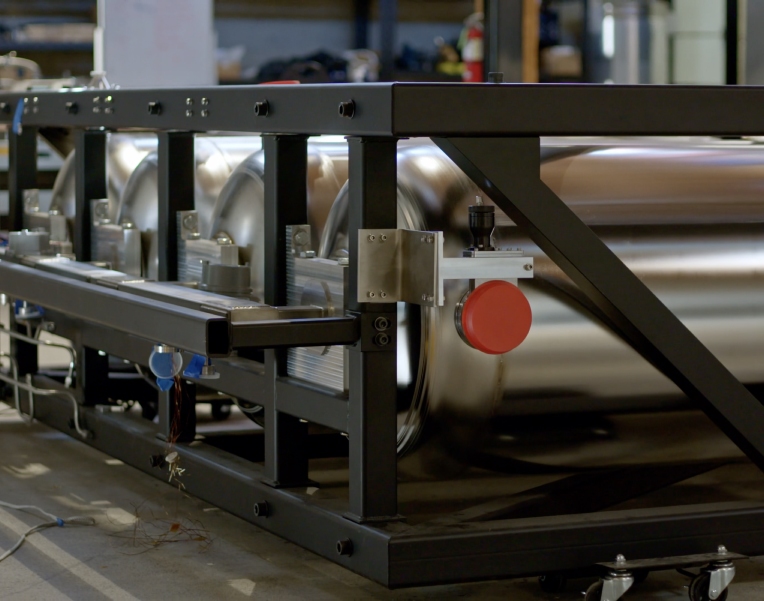

Single-tank system tested

Recently, the LLNL and Verne teams tested a single-tank system, demonstrating storage of more than 29 kilograms of cryo-compressed hydrogen.

This benchmark is three times greater than what has been previously demonstrated with any single CcH2 storage system and roughly equivalent to a one-megawatt-hour battery system, yet in a lighter and more compact storage unit.

The system is compact enough that it can fit where diesel tanks are typically installed on a Class 8 truck: on the side of the truck between the wheels. In addition to a different tank design, the components and functionality were enhanced to handle this larger volume.

“Despite the promise from early hydrogen-fueled truck pilots, the efficient storage of hydrogen onboard trucks, ships and planes remains one of the main challenges to unlock a zero-emission future,” said David Jaramillo, co-founder of Verne.

“Verne has developed high-density, lightweight hydrogen storage systems for use onboard heavy-duty vehicles at low cost. Our solution builds upon decades of research pioneered at Livermore to provide a reliable, scalable and cost-effective storage solution. We could not have done this without the team at Livermore. It’s exciting to see this project head toward the commercialization phase where it can be adopted across the heavy-duty sector.”