Mr. Frens’s career encompasses extensive experience with EPC contractors, technology development, investors, and project developers. He also heads his own company, BA2C zero emission molecule project development, which focuses on project development, particularly in Latin America. There, he works on hydrogen, biomass valorisation, municipal waste valorisation, and decarbonising existing industrial plants. Mr. Frens also often advises renewable energy and chemical companies, as well as investors venturing into the green molecule sector.

Mr. Frens, can you start by telling us about your background and how you got involved in the green hydrogen sector?

I studied chemistry, which gave me a broad understanding of chemical processes. My first job involved Independent Project Analysis (IPA), where I learned about the challenges and risks in developing, engineering, and constructing chemical plants and refineries. This experience provided insights into the complexities of multi-million/billion-dollar projects and how to deal with new and innovative technologies.

I then joined Tebodin (nowadays part of Bilfinger), a consultancy and engineering firm, where I developed projects in Central and Eastern Europe and started Tebodin’s office in Bulgaria. A brief stint at Capgemini Ernst & Young followed before I was contracted by Stamicarbon (part of Maire), the world’s largest fertiliser technology licenser, where, together with colleagues, I started up the project development department. This department evolved into NextChem and Met Development. About ten years ago, my work with hydrogen began at Stamicarbon, focusing initially on grey ammonia and fertilisers, laying the foundation for my involvement in the green hydrogen ecosystem.

At Brightlands Chemelot Campus, I focused on pilot plants where innovative chemical technology developers are supported. I then moved to TNO, working in the VoltaChem program, dealing with electrochemical processes like low-temperature CO₂ reduction, hydrogen production, and the integration of new technologies in industrial plants to reduce CO₂ emissions while keeping an interesting business case. At TNO, I also started up TNO’s molten metal methane pyrolysis programme, a process I regard as greener than green for its potential to produce hydrogen and solid carbon in one process without CO₂ emissions. One of the main advantages of this process is that hydrogen can be produced continuously and in high volume, a necessity for ammonia and other basic-chemicals production facilities.

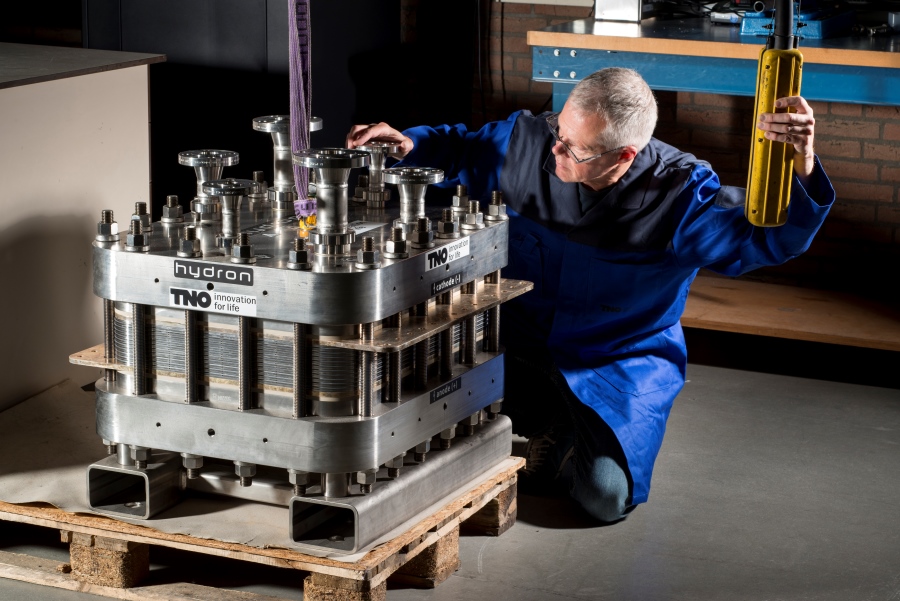

I am especially proud that at TNO I led the development of next-generation solid oxide electrolysers (SOEC) and initiated technology development projects with many of the SOEC OEMs, while at the same time gaining knowledge about other electrolyser technologies. Later, I joined McDermott as Global Energy Transition Advisor, learning even more about green hydrogen from an EPC perspective and working on safety aspects and hydrogen derivatives. After McDermott, I continued with HyCC, where I dealt with the development of green hydrogen (derivative) projects outside the Netherlands and Germany.

Since around the same time, I have also been advising French infrastructure asset investors on sustainable aviation fuel (SAF) projects in OECD countries and working with Climate Fund Managers from the Netherlands, focusing on locations in developing countries with great conditions for green hydrogen production, assessing green hydrogen (derivative) projects.

What are some locations you believe have optimal conditions for green hydrogen production, and why?

Locations like Egypt, South Africa, Colombia, Mexico, and Brazil are highly promising due to their low-cost renewable electricity, which in these countries can be combined with biogenic carbon (and CO₂) and/or iron ore, and which already have an experienced workforce. These countries also have potential local offtake markets for products like fertilisers and direct reduced iron (DRI) or even green steel, making them ideal for integrated projects without the need to export the green hydrogen. In contrast, places like Namibia and Chile, while excellent for green hydrogen production, might focus more on export of hydrogen or hydrogen carriers due to limited local demand initially. To improve the business case there, local offtake markets should be developed. The natural resources, including high solar and wind energy potential in these regions, make them particularly suitable for green hydrogen production and export of hydrogen carriers.

Can you elaborate on the importance of local offtake of hydrogen and its transport in the form of derivatives?

It is crucial to integrate hydrogen production with local offtake to reduce transportation and cracking/dehydrogenation challenges as well as loss of energy. Processing hydrogen into easily transportable products like DRI, fertiliser, iron fuel, and SAF is more efficient, cheaper, and more practical. For instance, Brazil, along with many other countries in Latin America and Africa, with its abundant iron ore resources and fertiliser needs, should focus on using hydrogen locally for the production of DRI, fertilisers, and SAF, which can also be used locally, rather than exporting hydrogen or ammonia, to produce the higher-value products elsewhere. This approach not only streamlines logistics but also maximises economic benefits for Brazil because by producing DRI, fertilisers or SAF, lots of value is created. Additionally, using hydrogen to produce such derivative products can significantly lower transportation costs and energy loss as well as avoids the complexities involved in handling and shipping hydrogen and converting hydrogen carriers back into hydrogen.

In your view, what are the most effective uses of hydrogen?

The key to effective hydrogen utilisation is to tailor its use to the specific conditions of each location. This means recognising the unique resources and industrial needs of different regions. For example, in the Baltics, the abundant biogenic carbon makes it suitable for producing SAF or methanol, which require carbon in their production processes.

In the Netherlands, while current conditions on land are not ideal, the future increase in offshore wind capacity will create favourable conditions for green hydrogen production, especially when offshore hydrogen production becomes feasible. However, simply producing hydrogen is not enough; we need to find practical applications for it, for example in a refinery or to supply it to existing ammonia plants in the Netherlands. However, in existing ammonia plants you can only replace part of the grey/blue hydrogen with green because existing ammonia plants need steam (for compression and recycles) and CO₂ (feedstock for urea), which are by-products from steam methane reforming processes. New ammonia plants, designed with modern engines for compression and recycling, and focused on export or carbon-free fertilisers, can handle up to 100% hydrogen but will likely be built in regions with cheaper continuously available renewable energy.

The European Union should focus on new technologies if it wants to stay competitive. Current high renewable energy costs make it unattractive for energy-intensive industries to build new plants in the EU, with the exception of Northern Europe, France, the Iberian Peninsula, and the Balkans. Policymakers need to decide whether to mandate or subsidise the use of green hydrogen in existing industries or allow these industries to relocate and import cheaper green products made in locations where conditions are favourable. In my opinion, the EU should focus on developing best technology and manufacturing equipment for green hydrogen (derivatives) to be deployed in countries where conditions are best.

If local conditions are suitable for integrating hydrogen into existing industries, it should be done. In the Netherlands, for example, hydrogen can be used as feedstock for existing ammonia plants and refineries. However, if these industries leave the Netherlands, locally produced hydrogen will still be needed for (specialty) industries that can afford to pay more for hydrogen. It might also find new applications in heating homes and electricity generation, taking advantage of seasonal storage benefits of hydrogen over electricity.

“Out-of-the-box thinking is crucial for utilising local resources effectively.”

Innovative technologies like HyAPC, a new oxy-fuel combustion technology to produce electricity, could for instance play a role in balancing electricity supply and demand during longer periods. This technology can be installed in new and existing gas-fired power plants using hydrogen and oxygen without NOx or CO₂ emissions. Such out-of-the-box thinking is crucial for utilising local resources effectively.

By focusing on local conditions and integrating hydrogen into appropriate industrial processes, we can maximise its benefits and support the energy transition.

What might be the implications of the evolving energy landscape for the EU?

History teaches us that industry follows energy, not the other way around. This trend has significantly impacted the location of heavy industries. In the EU, we see several companies relocating to regions where energy is more affordable. For example, in the past, the Netherlands attracted heavy industries due to its abundant and cheap coal and natural gas. However, with the decline of natural gas and coal, coupled with the relatively high cost of renewable energy, many industries are now considering moving to regions where renewable energy and other feedstocks like biogenic carbon/CO₂ and iron ore are cheaper and continuously available.

“History teaches us that industry follows energy, not the other way around.”

The EU needs to adapt by leveraging its strengths in technology development. We should focus on becoming leaders in new technologies and equipment manufacturing for renewable energy and green hydrogen (derivative) production. Investing in research institutions like Fraunhofer, DTU, and TNO as well as technology licensing and equipment manufacturers is crucial. The EU should aim to develop advanced technologies that can be deployed globally, particularly in regions with the best conditions for renewable energy. This approach will not only retain the EU’s competitive edge but also support the global energy transition.

In terms of approaches to hydrogen utilisation, can we draw any parallels with natural gas?

The World Bank and other institutions have developed a structured approach to deploying natural gas in countries with abundant natural gas resources. This strategy typically follows a step-by-step methodology that begins with local utilisation and gradually moves towards export as liquefied natural gas (LNG). Initially, natural gas is used to meet domestic needs such as heating homes and cooking. This ensures that the immediate energy requirements of the population are met efficiently. The next step, often simultaneously with the first one, involves supplying natural gas to local industries, such as bakeries and small manufacturing businesses, and using it in larger industrial applications that often need to be developed, like power generation, methanol and fertiliser plants, and refineries. This promotes economic growth and industrial development within the country. The strategy then focuses on building pipelines to neighbouring countries, enabling them to also use natural gas for similar local and industrial purposes. And finally, natural gas is exported through LNG to countries which lack sufficient energy for electricity generation and/or heating purposes.

In contrast, the approach to hydrogen, particularly in the EU, seems to start at the end. The focus is heavily on producing hydrogen for export in low-cost countries, similar to LNG, without first establishing robust local usage. It would be wiser to develop local markets for hydrogen, such as using it for producing fertilisers, methanol or SAF, which are easier to transport than hydrogen itself. This local-first approach would create a more stable and integrated market, reducing the complexities and costs associated with hydrogen transport.

There are currently four major electrolyser technologies that are being commercially deployed while undergoing further development: alkaline, PEM, SOEC, and AEM. Do you see any of them becoming predominant in the future?

SOEC is a game-changer due to its higher efficiency compared to PEM, alkaline, and AEM electrolysers. Despite some current challenges, such as mechanical strength, SOEC’s efficiency makes it a strong contender for the dominant electrolyser technology in the near future. It is particularly beneficial when integrated with processes like ammonia production, where it can utilise the exothermic reaction’s heat to further boost efficiency. SOEC’s ability to operate at high temperatures allows for greater conversion efficiencies, which is crucial for large-scale hydrogen production.

Having said that, while SOEC stands out due to its efficiency, especially in areas with high electriAcity costs, there will always be a need for other technologies based on their unique advantages. The goal is to find the right balance and leverage the strengths of each technology to optimise hydrogen production and utilisation. Continuous research and development are crucial to improving the performance and reducing the costs of all electrolyser types.

What role do you think policy plays in advancing green hydrogen technologies and projects?

Policy is vital in directing investments and fostering technological development. The EU, for example, should focus on leveraging its strengths in research and technology to support companies in developing cutting-edge solutions. Collaborating with regions that have favourable conditions for green hydrogen production is essential. This global cooperation can drive down costs and ensure a sustainable energy transition. Effective policies can incentivise the adoption of green technologies and create a favourable environment for investment and innovation.

What challenges do you foresee in achieving widespread adoption of green hydrogen?

One of the main challenges is the high cost of green hydrogen compared to grey hydrogen. Policy measures, such as carbon pricing and subsidies, can help bridge this gap. Additionally, public acceptance and market readiness are crucial; consumers and industries must be willing to pay a premium for green products until costs come down. Overcoming these challenges requires coordinated efforts from governments, industry, and the public. Investments in education and training are also essential to build the workforce needed to support the hydrogen economy.

What is your vision for the future of green hydrogen from now until 2050?

By 2050, my hope is that all hydrogen can be produced without CO₂ emissions. Achieving this requires significant advancements in technology, policy support, and global cooperation. Regions with optimal conditions should lead in production, while areas like the EU focus on technology development and equipment manufacturing. Ultimately, reducing our overall consumption and integrating innovative solutions will be key to a sustainable future.