According to the company, the development of its next-generation PEM stack platform, CHRONOS, is progressing as planned. As testing advances, the validation of several features will be completed, many of which will also be implemented into the current TRIDENT stack platform. The step-change reduction in iridium loading will be the first feature slated for adoption across both platforms.

ITM has retained all core science and manufacturing processes in-house, thereby maximising value-add, ensuring security of supply, and enabling rapid improvement and validation cycles.

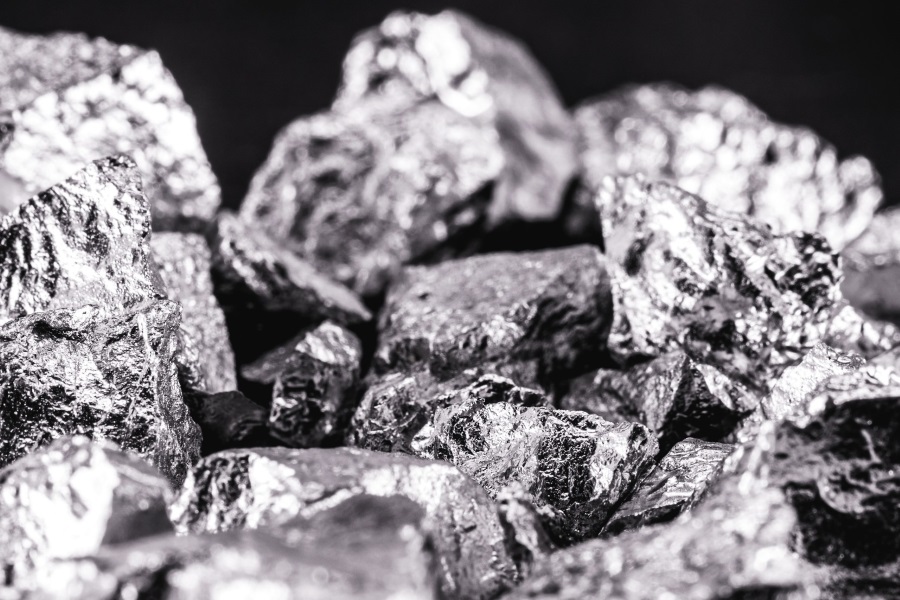

Dennis Schulz, CEO of ITM Power, said: “As part of a structured validation process, we have successfully reduced iridium loading by a further 40% without detriment to performance or degradation. As a costly raw material, reducing iridium benefits stack costs significantly. This loading reduction and our catalyst recovery and reuse processes will substantially reduce our consumption of critical raw materials and further lower our cost.”