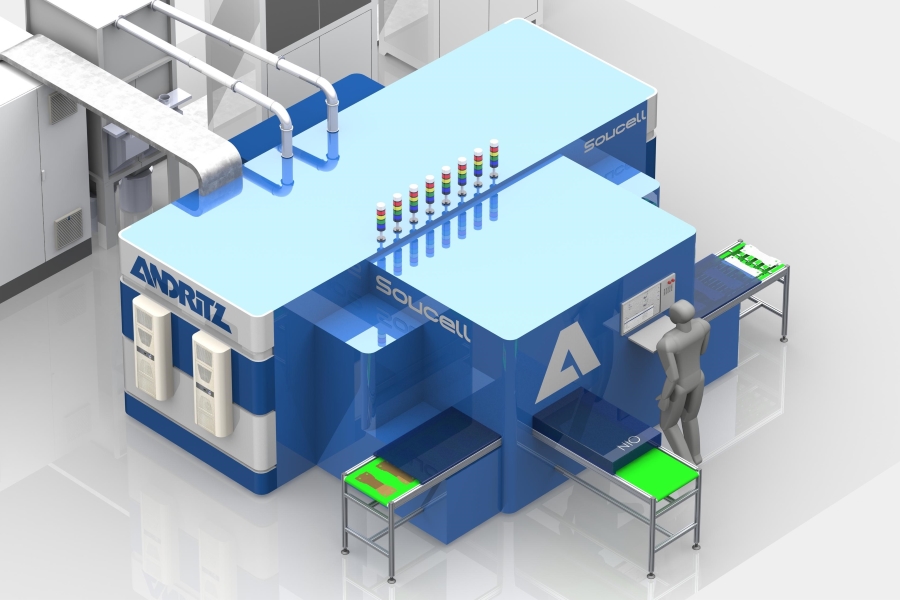

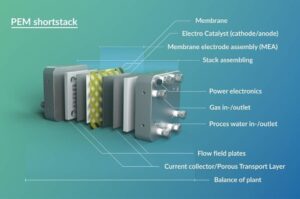

Sweden-based Cell Impact produces bipolar flow plates using proprietary high-speed forming technology. To boost its production capacity, the company plans to combine its technology with ANDRITZ’s advanced welding process. As part of the collaboration, ANDRITZ will complete the development of its new Soucell system. This multi-scanner (Galvo-Laser), on-the-fly welding system is capable of welding one bipolar plate per second (1 Hz), matching the throughput of the Cell Impact forming process.

The joint project will start in the first quarter of 2025, with the aim of installing a Soucell machine at Cell Impact’s production plant in Karlskoga by the second half of 2026. With the growing demand for bipolar flow plates, the scope of the collaboration is expected to expand.

Daniel Vallin, CEO of Cell Impact, said: “As we prepare for high-volume production, we have been looking for the right welding technology to complement our unique forming process. We are pleased to have found a partner in ANDRITZ that can support our ambitious goals.”

Daniel Wenk, VP Business Development at ANDRITZ Soutec, added: “We look forward to contributing to the transition towards sustainable energy together with Cell Impact. This collaboration is an exciting opportunity given Cell Impact’s exceptional capability to produce bipolar flow plates at an unprecedented scale.”