Swedish electrochemical process technology provider Permascand Top Holding AB and US water electrolysis technology provider Verdagy have agreed to collaborate on the development of a novel electrochemical cell to produce green hydrogen. The collaboration aims to accelerate the commercialization of the electrochemical cell that is the foundation for the Verdagy Water Electrolysis (VWE) process.

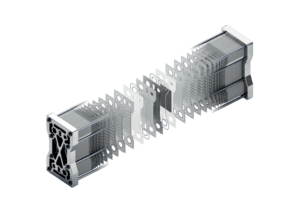

Verdagy and Permascand will work together to develop and commercialize a novel large aspect ratio electrolysis cell capable of managing the heat and stress created by operating at much higher current densities than currently available with today’s water electrolysis technology. The nearly three-square-meter cell and membrane architecture is key to dramatically lowering the upfront capital costs of a cell and system. Taken together, very large cells operating at high current densities are more productive, thereby lowering hydrogen production costs. By partnering, Verdagy and Permascand hope to bring this technology to the broader market with the unprecedented speed necessary to accomplish the goals of Net Zero.

“Permascand is a great partner to bring our cell design to commercialization. Their focus on reproducibility and reliability along with the ability to competitively manufacture large quantities of large format electrochemical cells will be invaluable in the rapid commercialization of the VWE process,” said Marty Neese, CEO of Verdagy.

Verdagy is currently modifying its pilot plant facilities in Moss Landing, California, to operate 200kW cells at current densities two to four times higher than the nearest competitor. Having a full-capability pilot plant and an experienced team of electrochemists, process engineers and plant operators in place is expected to provide Verdagy with a rapid path to commercialization.