The demonstration facility is intended to validate Syntholene’s hybrid thermal production approach to producing low-cost hydrogen feedstock for eSAF and other eFuels, with scalability, energy efficiency, and long-term cost competitiveness with fossil fuels as primary objectives. Syntholene has secured 20 MW of dedicated energy to support the plant and commercial scale-up.

For Syntholene, the vendor choice marks a key technical milestone as it advances engineering and procurement for its first demonstration-scale project after a two-year technical and commercial evaluation of major electrolyzer vendors.

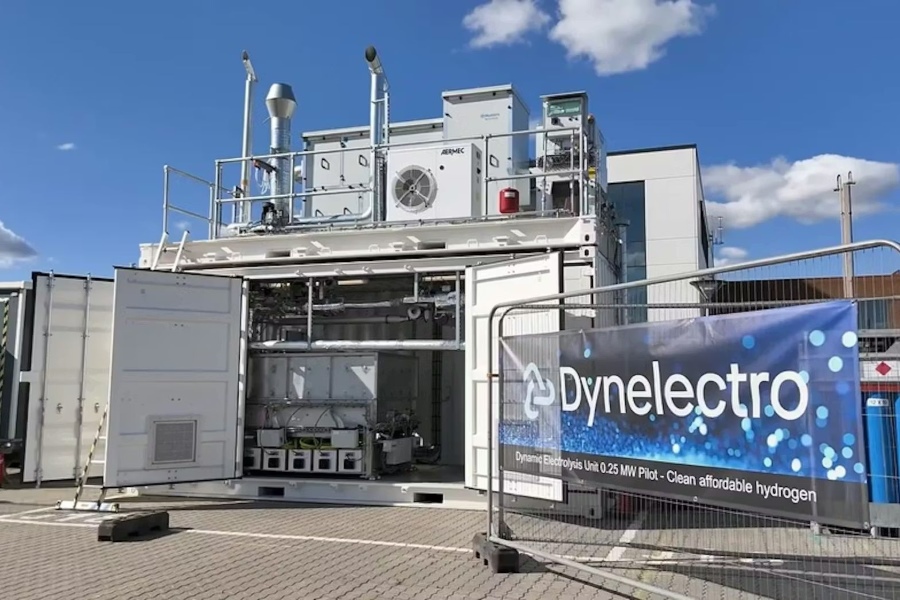

“Syntholene’s eSAF production plans are a perfect match for Dynelectro’s electrolyser solution,” said Sune Lilbaek, CEO at Dynelectro ApS. “To be successful in the eSAF market, the lowest possible cost of hydrogen over the lifespan of the plant is a necessity. Dynelectro’s unique take on SOEC electrolysers seeks to enable the lowest possible energy consumption and maintenance cost. When integrated with Syntholene’s proprietary hybrid thermal production system, it is possible to convert up to 90% of the renewable electrical energy supplied into clean hydrogen. Together, we expect to be deploying the most cost-effective, energy-efficient solution for production of sustainable aviation fuel on the market today.”

“The selection of Dynelectro is the result of a rigorous two-year technical and commercial evaluation process across all major vendors focused on efficiency, reliability, and long-term scalability,” said Dan Sutton, CEO of Syntholene. “Electrolyzer performance coupled with low-cost clean energy are the primary drivers of synthetic fuel economics. Partnering with a technology provider that prioritizes energy efficiency and industrial robustness is critical as we move from demonstration toward multi-megawatt commercial deployment.”