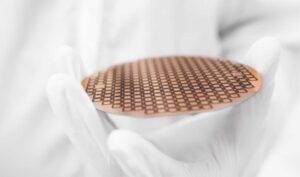

As part of a broader collaboration with ANDRITZ, HydrogenPro recently completed a full-scale validation test of its Generation 3 electrolyzer technology at Herøya, Norway. The system operated continuously for 500 hours, confirming expected performance levels and product quality. Safe operation was maintained across the full load range – from partial load up to 115% capacity – demonstrating the robustness and industrial readiness of the technology under real-world conditions.

The validation project involved several European facilities: electrodes were manufactured in Denmark, stack assembly was carried out in Erfurt, Germany, and the system was transported and commissioned in Norway. The initiative highlights a strong European value chain for pressurised alkaline electrolyzers and supports key decarbonisation efforts in hard-to-abate sectors such as low-carbon steel production.

ANDRITZ, HydrogenPro’s project partner, recently announced a planned 100 MW electrolyzer project in Rostock, Germany. Subject to the final investment decision, ANDRITZ expects to receive the notice to proceed with the supply of HydrogenPro electrolyzers for the project.

In addition, HydrogenPro has secured a separate purchase order for electrolyzers worth USD 2.5 million from an undisclosed customer.