Hydrogen-ready by default

PRUSS has delivered over 30 valve packages for gas turbine power generation projects with hydrogen capabilities. As Drehmel explains, “Every gas turbine project we supply today includes a hydrogen option. Even if the plants are initially powered by natural gas, our customers are preparing for a hydrogen future.”

These projects span the globe, from China to the United States, with Saudi Arabia emerging as a surprising frontrunner in hydrogen readiness. “Even the world’s biggest oil producers are building energy infrastructure that is hydrogen-capable,” Drehmel notes. “It’s a global trend.”

Some of the installations PRUSS supplies reach up to 593 MW in capacity, highlighting the critical role their valves play in some of the world’s largest hydrogen-ready power plants.

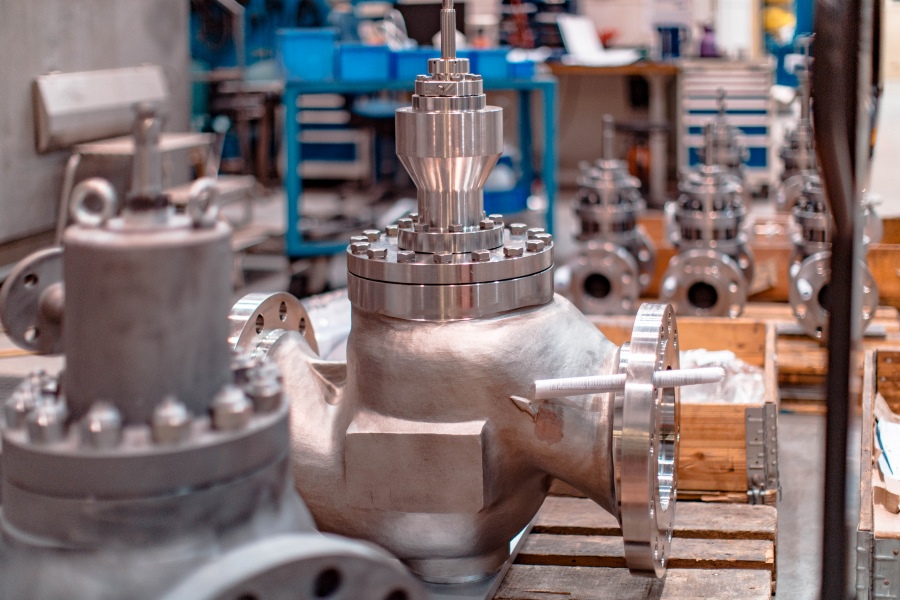

A typical package from PRUSS includes up to 14 valves – highly precise control valves with integrated shut-off functions, supported by quick-acting emergency shut-off valves. Designed to handle gas temperatures exceeding 300°C, these valves are made from carefully selected materials that can withstand the embrittlement risks and other challenges associated with hydrogen at elevated temperatures.

“Every gas turbine project we supply today includes a hydrogen option.”

These solutions are tailored for demanding conditions, offering rangeabilities up to 500:1, which allows for highly responsive and accurate flow control, especially during ignition and load changes. This level of control not only enhances safety and efficiency but also helps reduce overall system costs by eliminating the need for multiple valves performing similar functions.

While details remain confidential, PRUSS has also developed a new valve series tailored to a leading turbine model in the 60 Hz market. “This model is expected to become the new workhorse,” Drehmel says. “We’re prepared to handle the expected ramp up to several dozen in the coming years.

Beyond combustion

Although gas-fired power generation remains PRUSS’s core hydrogen market, the company is cautiously extending its reach into other segments.

“We are a high-pressure valve specialist, so storage and transport systems are not our focus,” Drehmel explains. “But in hydrogen production, we see opportunities – particularly in oxygen recovery from electrolysis.

Wet oxygen, a by-product often vented to the atmosphere, presents a promising application. “We’re working with clients on systems to recover and reuse this oxygen at industrial scale,” says Drehmel. “We believe there is untapped potential in this area, and our engineering team is closely collaborating with partners to develop robust, safe, and cost-effective valve solutions.”

Meanwhile, PRUSS has made headway in cryogenic valve technology. Targeting applications such as bypass valves in compression stations and pressure reduction from liquid hydrogen storage to gasification, the company is developing a multistage, metal-sealed solution. “The aim is to minimise leakage, reduce noise, and achieve maintenance-free operation,” Drehmel explains.

The prototype is undergoing testing, with commercialisation planned for 2026. “We are conducting external leakage and functional tests with a laboratory in the Netherlands,” he says. “The results will support our marketing efforts and customer engagement.”

A key innovation lies in the elimination of dynamic elastomeric gaskets, replacing them with metallic sealing technology. This significantly extends service intervals and allows for longer operational uptime, which is particularly important in remote or high-risk installations where maintenance activities are logistically complex and costly.

Fuel gas metering valves for pure hydrogen service, a previously announced R&D project, have also reached maturity. “We’ve delivered several units, and customer feedback has been positive,” Drehmel confirms. “We adapted technology from our cryogenic valve development to achieve maintenance-free performance.”

The importance of reliability in this context cannot be overstated. As Drehmel notes, “When we deliver a valve, it may not enter service until one or two years later. This means the product must meet the highest standards from day one. There is no room for error.”

Sustainability as a strategy

Beyond product development, sustainability has become a major theme for PRUSS. Although the company is not legally required to produce a sustainability report, its parent company, Certina Holding, has pushed for compliance. Drehmel views this not as a burden, but as an opportunity.

“We realised we were already doing many good things,” he says. “Switching to LED lighting, digitising our processes, using frequency-controlled compressors, offering electric company cars and bike leasing – all of these contribute.”

PRUSS also supplies valves for heat pumps, carbon capture projects, and, of course, hydrogen applications. “It made sense to compile our efforts and make them visible,” Drehmel explains. “Sustainability reporting is not just about compliance – it’s about communicating who we are.”

However, he acknowledges the challenges. “Each year, you must show improvement. That is difficult for a production facility under cost pressure, especially when outsourcing basic machining to Asia introduces transport emissions. Still, monitoring is the first step.”

Efforts are also under way to make sustainability part of the corporate DNA. “We are educating our teams, initiating internal campaigns, and involving employees in identifying areas of improvement,” says Drehmel. “It’s a cultural shift that empowers everyone to play a role.”

“Sustainability is a cultural shift that empowers everyone to play a role.”

In parallel, PRUSS is also reviewing its supplier base to prioritise partnerships with companies that uphold comparable environmental and social standards. “Sustainability is no longer a stand-alone objective. It’s becoming part of our decision-making matrix – from procurement and logistics to customer engagement,” Drehmel adds.

Making more with more

Machining capabilities at PRUSS have evolved significantly. “We are not only expanding our capacity but shifting it,” Drehmel clarifies. “Basic machining has moved to Asia, while high-precision, high-tech machining remains in Hanover and is being expanded.”

This strategic division enables PRUSS to handle increasing order volumes while maintaining quality. “We assemble, test, and complete all complex machining in-house,” says Drehmel. “This way, we address cost pressures without compromising performance.”

Investments in automation and robotics have further streamlined operations. “After our last interview, we added a robotic machining centre to our Hanover facility,” Drehmel says. “In between, we also integrated an additional lathing centre, and now the next machine is already on order.” These incremental but continuous investments help PRUSS remain competitive while addressing the skills shortage in the German labour market.

The result is a manufacturing process that balances global efficiency with local excellence. “We see this as a hybrid model that combines cost-effective sourcing with German engineering standards,” Drehmel says. “This dual-track approach is allowing us to scale up smartly.”

A service ecosystem

To support its growing global customer base, PRUSS continues to invest in its distribution and service network. While many sales and service partners are well established, the company is filling gaps and raising standards.

“We are training our partners more intensively and building up service centres in the Far East,” Drehmel reveals. “It’s difficult to find people in Germany willing to travel globally, so we are working with local partners to deliver service as per our specifications.”

This approach ensures fast, reliable after-sales support for customers worldwide. PRUSS also maintains regular communication with partners, offering training sessions, documentation updates, and direct engineering support to solve complex problems.

The company is also exploring remote service capabilities using digital tools and diagnostics. “There is room for digitalisation in service,” Drehmel says. “We are piloting new methods that allow us to support partners and clients even when we cannot be there physically.”

A long view

Reflecting on PRUSS’s 135+ years in business, Drehmel credits adaptability for the company’s longevity. “We would not have survived without constantly adjusting to new regulations, technologies, and market conditions,” he says. “Sustainability is part of that. So is innovation.”

“Hydrogen is one of several trends shaping the future,” Drehmel continues. “Others include digitalisation, decentralised energy systems, and changing customer expectations. We want to be at the forefront of these shifts, not just reacting but shaping outcomes.”

“Everyone is preparing for hydrogen – and we are ready.”

Despite uncertainty in global energy policy, PRUSS is confident in its direction. “No one knows what next week will bring,” says Drehmel. “But everyone is preparing for hydrogen, and we are ready.”