Developed by the Helmholtz-Zentrum Dresden-Rossendorf (HZDR) and start-up MAGNOTHERM, the demonstrator marks a breakthrough in sustainable, energy-efficient magnetic cooling and paves the way for large-scale industrial application.

Dr. Tino Gottschall, scientist at HZDR’s High Magnetic Field Laboratory Dresden (HLD), has long envisioned a plant capable of producing 5,000 kilograms of liquid hydrogen per day, which he says would be significantly more efficient and affordable than today’s liquefaction methods. Together with MAGNOTHERM and other HyLICAL partners, his team is now working to prove that hydrogen liquefaction based on the magnetocaloric effect can be scaled for industrial deployment.

Since 2023, HZDR and MAGNOTHERM have combined academic expertise with entrepreneurial innovation to advance magnetocaloric cooling technologies. “Our magnetic cooling technology represents a new type of climate-friendly and energy-efficient alternative, without compressors and environmentally harmful refrigerant gases. This will enable us to significantly accelerate the necessary climate tech transformation within the refrigeration industry,” says Timur Sirman, co-managing director of MAGNOTHERM.

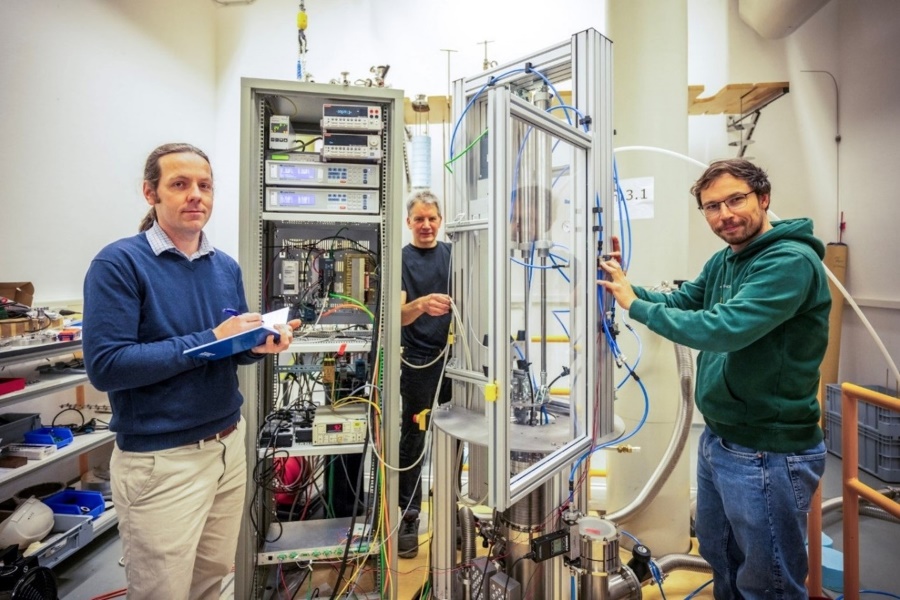

In 2024, MAGNOTHERM opened a second facility on the Rossendorf campus and established a joint laboratory where Gottschall and MAGNOTHERM engineer Thomas Platte have built the hydrogen liquefaction pilot plant. At its core is a 19-tesla superconducting magnet embedded in the floor of the HLD – by comparison, modern MRI machines in medicine use magnets with a strength of 1.5 to 3 tesla. “We can now use this plant to prove the principle and how it works,” says Gottschall. The next target is to increase efficiency to produce 100 kilograms of liquid hydrogen per day to demonstrate scalability for industrial deployment.

The demonstrator is based on the magnetocaloric effect, which occurs when materials such as the lanthanum-iron-silicon alloy (LaFeSi) are placed in a magnetic field, causing a sudden rise or drop in temperature depending on the orientation of the magnetic moments. Using this principle, hydrogen can be cooled to –253°C following pre-cooling with liquid nitrogen, at which point the gas begins to liquefy. “Our method offers significant advantages for hydrogen liquefaction,” notes Gottschall. “With the MAGNOTHERM joint lab at HZDR, we aim to reduce liquefaction costs to below €1.50 per kilogram of hydrogen, compared to conventional plants.”

The launch of the pilot plant marks a key step in HyLICAL’s mission to advance energy-efficient, compact hydrogen liquefaction technologies based on magnetocaloric cooling. By validating this approach at pilot scale, the project supports Europe’s ambition to produce green hydrogen more cost-effectively, reduce transport costs, and accelerate the transition to a climate-neutral energy system.