This offers a critical layer of protection for pipelines and downstream components and promotes the safe storage of hydrogen post-production, prior to its transportation to the point of use.

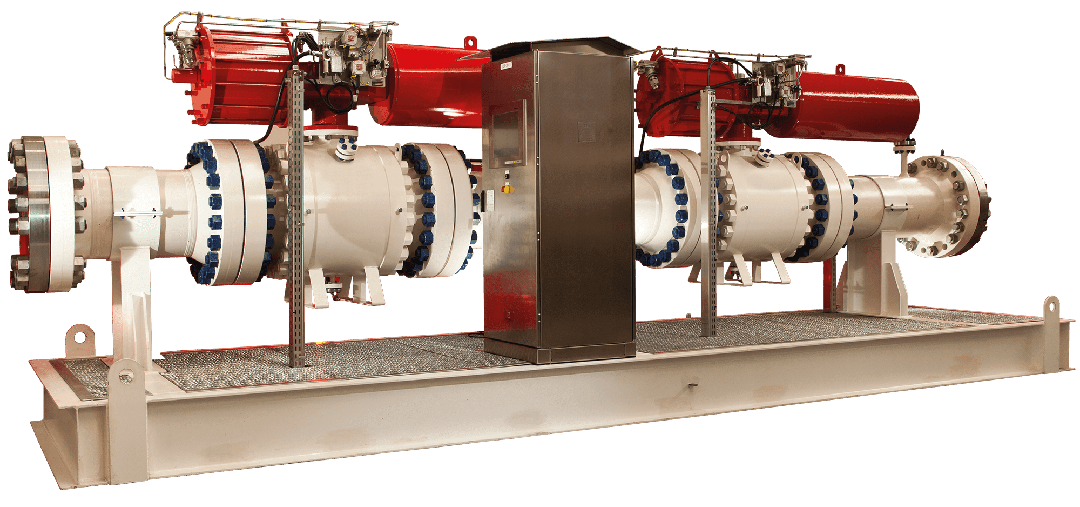

The system uses electronic transmitters specifically designed for hydrogen applications and an electronic logic solver to sense a potential overpressure event. If triggered, failsafe valves will be activated within two seconds to isolate the exposure and protect the downstream assets and plant personnel.

Andrea Pusceddu, Business Development Director for Hydrogen at IMI, said: “Hydrogen has huge potential to support with reducing CO₂ emissions in hard-to-abate sectors such as heavy industry and long-distance transport. With the International Energy Agency predicting these applications could account for one-third of global hydrogen demand by 2030, guaranteeing the safety of both the production team and plant equipment will be one of most important priorities for all stakeholders.

“With long-standing expertise in delivering HIPPS systems for a range of severe service applications throughout the process industry, combined with a rapidly developing suite of solutions for the hydrogen value chain, we have been able to call upon our knowledge of both disciplines to create what we believe to be the first HIPPS for hydrogen. Not only will this help our customers’ facilities become safer, but it can also help to increase uptime while increasing revenue potential.”