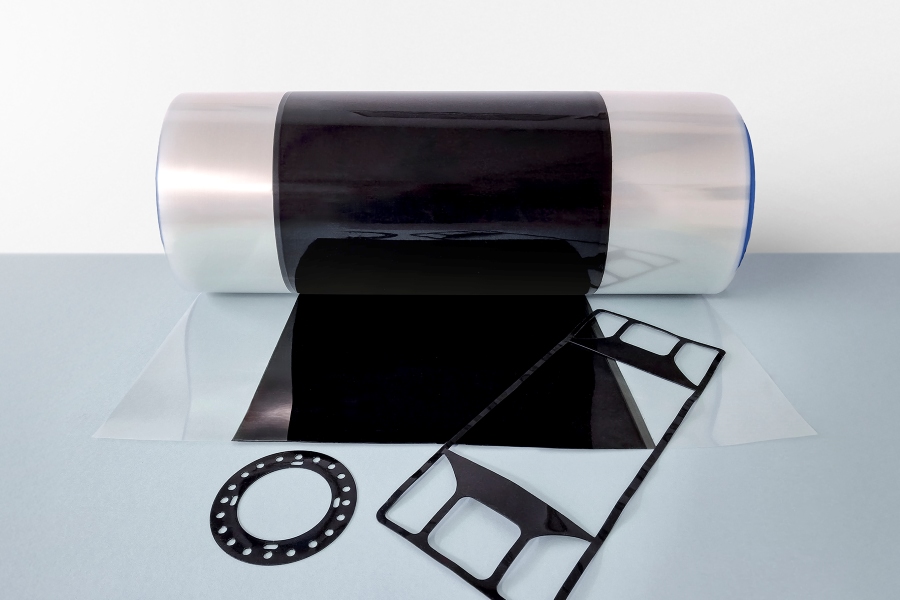

In the process, Wevo’s specially formulated two-component elastomers are applied in liquid form to a carrier film using Laufenberg’s coating equipment. Curing takes place in a multi-zone tunnel oven, with optional infrared pre-curing to shorten cycle times and remove air bubbles. Line speeds between 0.5 and 50 m/min allow flexible scaling, with the resulting tack-free material delivered either as rolls or as precision-cut gaskets.

The technique allows the production of pure elastomer gaskets with thicknesses from 20 µm to 2 mm, as well as hybrid seals ith carrier films up to 4 mm in total thickness. Depending on application requirements, the carrier film can either be removed after curing or retained to enhance dimensional stability and pressure resistance.

Wevo contributes its expertise in silicones and modified polyurethanes with low hydrogen permeation, already used as liquid sealants and adhesives in fuel cell and electrolyser stacks. Laufenberg brings long-standing know-how in silicone coating. Together, the companies provide manufacturers with a cost-efficient, high-throughput solution for producing prefabricated gaskets tailored to hydrogen and battery technologies.