A legacy of continuous innovation

Founded by the Greene brothers and Henry A. Tweed, Greene Tweed has grown from its beginnings into a global leader in high-performance materials. “Being a privately held, family-owned company allows us to focus on long-term goals rather than short-term financial metrics, which is crucial in the hydrogen sector where development cycles can be extensive,” says Philippe Allienne, Business Development Manager – Clean Energies. This ownership structure underpins Greene Tweed’s ability to sustain significant investments in research and innovation – a necessity in sectors like hydrogen where rapid advancements are key.

Philippe elaborates on how this long-term perspective drives their operations: “In an industry like hydrogen, patience and sustained investment are essential. The projects we engage in often span years, from the early concept phase to commercialization. A short-term approach would never allow for the level of commitment required to bring meaningful solutions to market.”

This commitment to innovation is further strengthened by Greene Tweed’s integrated approach to material science and application development. By embedding material formulation expertise within the company, Greene Tweed can tailor solutions to specific industry challenges. “We fine-tune our material recipes based on application needs,” Philippe explains. “Our iterative development process involves testing solutions directly with customers and refining them based on feedback, enabling faster innovation cycles – essential in a fast-evolving market like hydrogen.”

Advancing PEEK through cross-linking

At the core of Greene Tweed’s advancements in hydrogen applications is its pioneering work with PEEK (Polyether Ether Ketone), a high-performance thermoplastic polymer known for its exceptional mechanical strength, chemical resistance, and thermal stability. “We found a way to improve the performance of PEEK materials by cross-linking them,” Philippe explains. “This process creates additional bonds between molecules, enhancing chemical compatibility, mechanical strength, and temperature resistance.”

Evolution of Arlon 3000XT®

This cross-linked virgin PEEK material provided the necessary chemical and mechanical properties for downhole connectors. The transition to hydrogen leveraged this experience. “The high pressures, temperatures, and aggressive media in hydrogen applications are similar challenges,” Philippe notes. “3000XT became a foundational material for critical components like valve seats and seals.”

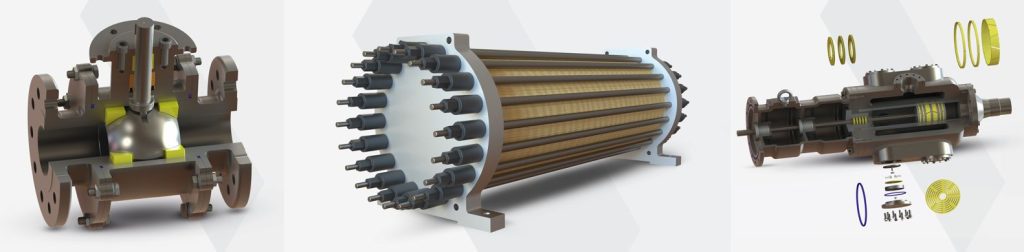

Boosting efficiency and durability in electrolyzers and fuel cells

Hydrogen production through water electrolysis is one of the most promising methods for generating clean hydrogen, but it presents specific material challenges. Electrolyzers operate under demanding conditions, often involving aggressive electrolytes like potassium hydroxide (KOH) or acids, coupled with increasing pressures and temperatures aimed at improving efficiency. Traditional materials often fail to withstand such demanding environments.

In fuel cells, contamination from extractables in materials can poison the system, while creep resistance becomes critical as designs move toward higher pressures and temperatures to boost efficiency. “Fuel cells are a prime example of where the right material choice can make or break a design,” Philippe notes. “Our materials are tailored to meet these needs, ensuring reliability in everything from thin gaskets to structural components.”

Meeting the increasing demands of hydrogen storage and distribution

Enhancing hydrogen compression with cutting-edge materials

Compression is a critical step in the hydrogen value chain, with hydrogen’s distinctive properties posing significant challenges for traditional systems. Greene Tweed is rising to meet these challenges with cutting-edge materials designed to redefine performance standards.

On the centrifugal compressor side, Philippe highlights another challenge: “Hydrogen’s very low molecular weight makes it difficult to compress the gas in a centrifugal compressor. Indeed, the compression ratio between impeller stages is a square function of the impeller’s tip speed and inversely proportional to the molecular weight of the gas. For hydrogen compression it is therefore necessary to increase the tip speed beyond the strength of current metallic impellers as their high density induces destructive centrifugal forces.”

“Our materials and components enable new technologies and applications previously unattainable.”

“Our second-generation composite impellers have already surpassed tip speeds of 500 meters per second,” Philippe says. “We are collaborating with compressor OEMs to refine our designs further, aiming for 620 meters per second – a goal that remains out of reach for traditional metals. These impellers not only improve efficiency but also extend the lifespan of compressor systems by mitigating embrittlement and wear.”

The company’s R&D teams in the U.S. and Switzerland continue to advance this technology, with a third iteration of composite impellers already under development.

Arlon® 3160XT: a groundbreaking material

Arlon® 3160XT is a new glass-reinforced, cross-linked PEEK material designed for fuel cell, electrolyzer, and valve components, launched in January 2025. With exceptional creep resistance and electrical insulation properties, Arlon® 3160XT represents a significant advancement in materials science, addressing critical needs in hydrogen applications.

Arlon® 3160XT tackles significant material challenges in scaling hydrogen production, storage, and utilization by enhancing performance and reliability in key hydrogen systems. Building on the capabilities of Arlon 3000XT®, this new grade delivers improved performance in the most demanding environments.

Arlon® 3160XT offers several key features that set it apart. Its creep resistance is over 20 times greater than that of non-cross-linked glass-filled PEEK, ensuring long-term durability under sustained mechanical loads. It also demonstrates significant improvements in elevated temperature mechanical properties (tensile, flex, and shear), with a 30–70% enhancement compared to standard glass PEEK materials. In addition, Arlon® 3160XT maintains excellent electrical insulation properties, resisting degradation in critical electrochemical cells and enabling long operational lifespans. Laboratory tests also indicate improved flame resistance, with enhanced structural integrity following flame exposure.

Shaping the hydrogen economy

As hydrogen gradually establishes itself as a key element in the clean energy transition, Greene Tweed is committed to enabling its growth through innovation and collaboration. “Existing materials are often inadequate for the demands of hydrogen applications,” Philippe observes. “That’s where we come in. Our materials and components not only solve problems but also enable new technologies and applications previously unattainable.”

“We are not just a supplier – we are a partner in innovation.”

By addressing the challenges across production, storage and transportation, and utilization, Greene Tweed plays a vital role in shaping the future of hydrogen. “We are not just a supplier – we are a partner in innovation,” Philippe says. “Together with our customers, we are creating solutions that will power the transition to clean energy.”

Discover Arlon® 3160XT’s breakthrough capabilities

Greene Tweed invites industry professionals to join an engaging webinar on 26 February 2025 at 9:00 AM EST (GMT+9). This session will provide an in-depth introduction to Arlon® 3160XT and its applications, highlighting the role of the company’s innovations in advancing hydrogen technologies..

If you cannot attend live, a recording will be available on the company’s website. Visit the Greene Tweed webinar page to register or view the recording.