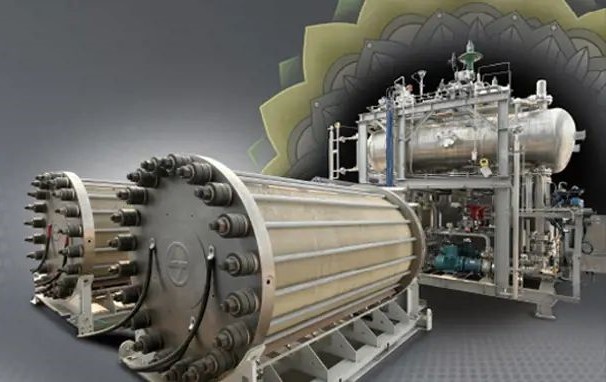

Featuring a rated power capacity of 1 MW (expandable to 2 MW), this electrolyser can produce 200 Nm³/Hr of hydrogen. It is equipped with two stacks and an Electrolyser Processing Unit (EPU) ML-400, which is indigenously manufactured and assembled, adhering to the latest international standards, and offers exceptional flexibility and thermal stability, according to the company. The electrolyser will now undergo rigorous testing in the coming weeks to optimise its performance, paving the way for full-fledged manufacturing of electrolysers.

L&T Electrolysers, a newly incorporated entity of L&T, is focused on manufacturing pressurised alkaline electrolysers using the technology from McPhy Energy, France. The company spearheaded the complete value chain from engineering to manufacturing, in collaboration with Indian vendors and suppliers, thus setting a benchmark for ‘Make in India’ initiatives. L&T Electrolysers plans to leverage its upcoming giga-scale facility in Hazira to meet the growing demand for green hydrogen, maximising product localisation through enhanced local supply chain, and automation for cost-competitiveness.

Subramanian Sarma, Director & Sr EVP (Energy) at L&T, said: “The indigenously manufactured electrolyser marks a transformative leap towards clean energy, positioning us to lead not only in the domestic market but also globally. This advancement significantly bolsters our offerings across the value chain, showcasing L&T as a global force in the clean energy space.”

L&T Electrolysers has been allocated a significant 300 MW/annum capacity under the Production Linked Incentive (PLI) of the National Green Hydrogen Mission, launched by Government of India’s Ministry of New and Renewable Energy (MNRE) and implemented by the Solar Energy Corporation of India (SECI).