In the course of the energy transition, the use of hydrogen as an energy carrier represents one of the key technologies. Particularly in hydrogen transport and in tank systems for fuel cell vehicles, the highest demands are placed on the sealing materials used, since leakage cannot be tolerated due to explosiveness. The use of elastomer seals is firmly established in the current natural gas infrastructure and thus also represents a key component for hydrogen transport. Elastomer seals are also the focus of attention regarding the continued use of existing pipeline systems for hydrogen, although the medium of hydrogen once again poses special challenges for the sealing elements used.

The system pressure in initial series applications of hydrogen tank systems is 350 bar, with future developments aiming at applications with 700 bar nominal pressure or beyond. In addition to the enormous stresses placed on the seals by the pressure, there are also temperature ranges of -40°C to 85°C that can occur during refueling operations. Due to the small molecular size of hydrogen, the migration of hydrogen into and through the sealing elements must also be considered. On the one hand, this leads to swelling of the sealing elements, which must be considered for component design. On the other hand, hydrogen absorbed by the material can lead to abrupt volume expansion in the event of a sharp drop in pressure, which can damage the component so that rapid escape of the gas from the sealing body is possible. In addition to the high demands placed on the nominal properties of the seals, elastomer materials can be expected to experience aging effects over their service life, which change the sealing properties. These effects are also strongly influenced by acting mechanical loads, temperatures and media and must therefore also be considered in the design.

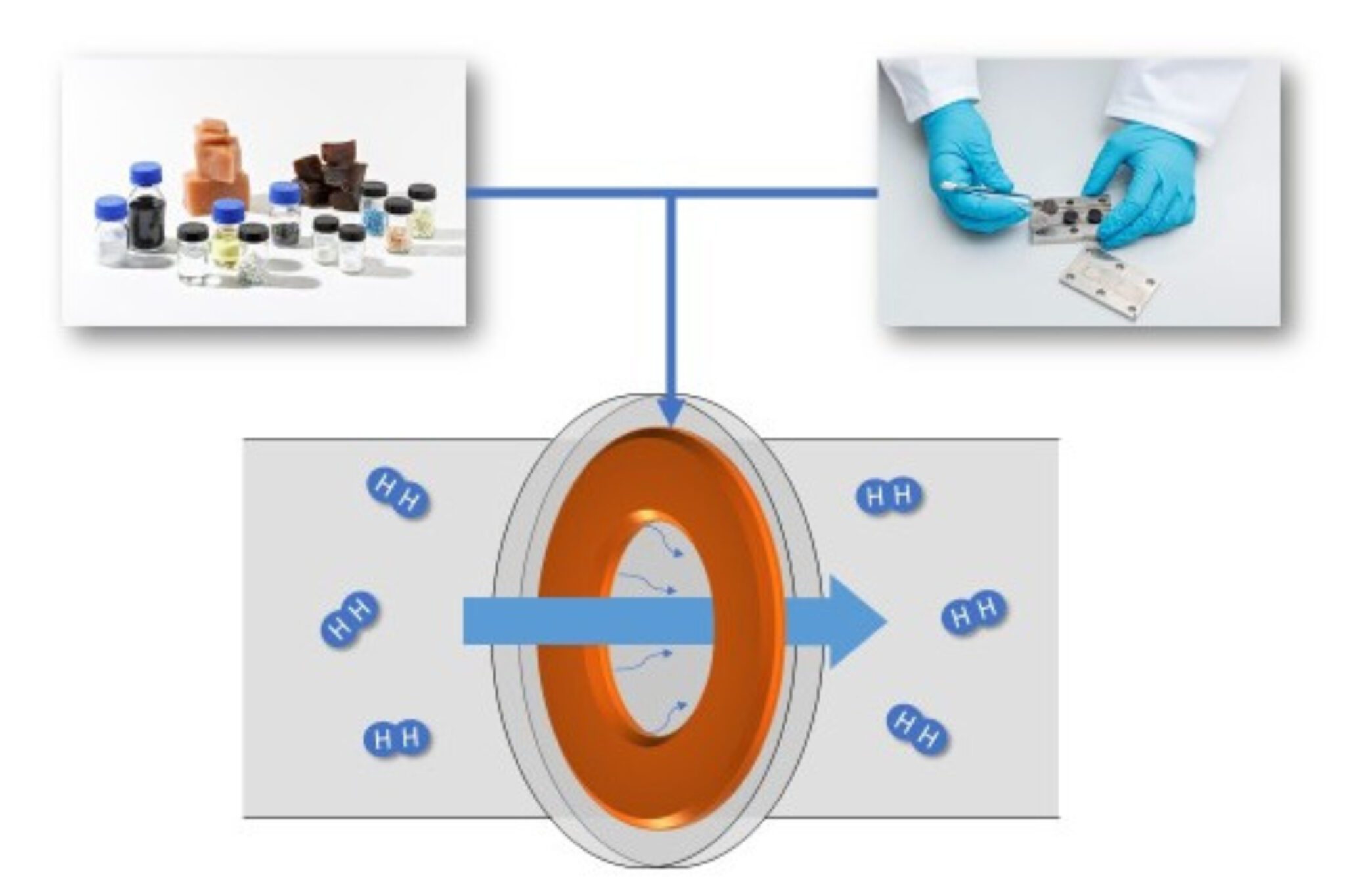

Until now, only a few reliable findings exist on the use of elastomers in combination with hydrogen. The aim of the HydroTransSeal project is to understand the interaction mechanisms of hydrogen with elastomer materials and to take appropriate measures to make the materials more robust to permeation, adsorption and swelling when in contact with hydrogen (e.g., by selecting suitable fillers and additives). Currently, hydrogen is still transported primarily by tank trucks and few pipeline systems exist. It is therefore necessary to evaluate elastomer seals used in existing pipeline systems regarding their suitability for hydrogen transport and, if necessary, to qualify them for use in order to simplify hydrogen transport. By developing a material and aging model, it will be possible to estimate the service life of elastomer materials based on their aging-dependent behavior. In the long term, this will make it possible to optimize the compounds for the area of application. The project should also be an incentive for raw material suppliers in the field of elastomers to place innovative elastomer formulations in the promising field of hydrogen transport and to initiate new developments for these systems.

More information about the HydroTransSeal project and how to join it can be found here.